In 2024, Florida faced catastrophic hurricane damage due to a series of powerful storms, which caused widespread devastation across the state. Many areas, especially along the Gulf Coast and the Atlantic coastline, saw homes, businesses, and infrastructure destroyed.

The situation has highlighted the urgency of improving coastal resilience and disaster preparedness. When powerful storms strike, a standard home often struggles to hold up against high winds, heavy rain, and flooding. A hurricane-proof house is designed to handle these forces with stronger materials, smarter layouts, and features that keep the structure intact like steel framing, impact-rated windows, and elevated foundations.

Modern options also make hurricane protection more accessible. Prefab and modular homes are prime examples of lower costs and faster construction. By exploring materials, construction methods, and innovative designs, anyone in a storm-prone area can find a safer way to build.

Essential Materials and Construction Techniques

Building a hurricane resistant home depends on using materials that can resist hurricane winds, heavy rain, flying debris and other secondary extreme weathers. Strong structural systems, reinforced walls, and protective windows all play a role in reducing damage and keeping the home safe.

Concrete and Masonry

Concrete and masonry remain some of the most reliable choices for hurricane-resistant construction. Reinforced concrete walls can withstand extreme wind pressure and resist water intrusion better than wood framing. Masonry blocks, when filled with steel reinforcement and concrete, provide added strength and stability. They ensure the proper anchoring of the walls to the foundation, which is essential to prevent uplift during strong storms.

When combined with impact-resistant windows and doors, a concrete or masonry structure offers one of the highest levels of storm protection available in residential design.

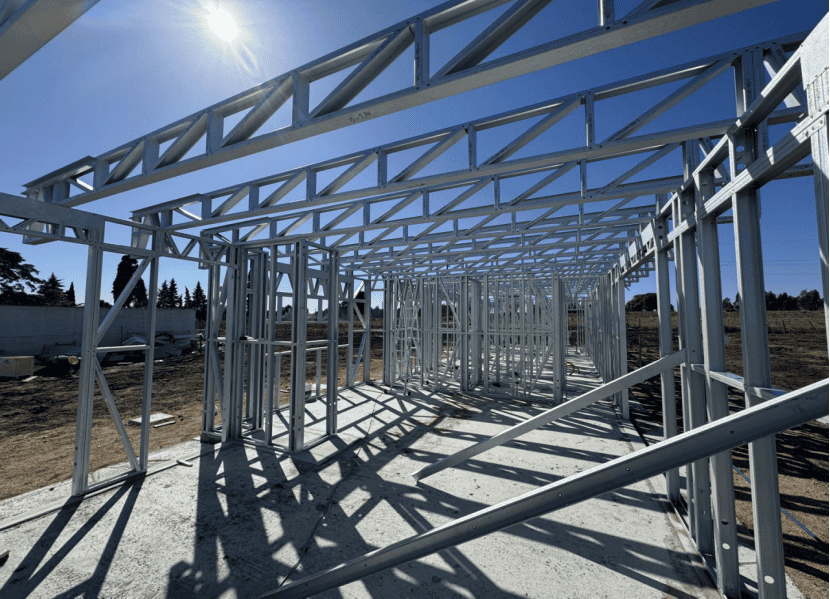

Light Steel Frame Construction

Light Steel frames provide another strong option for hurricane-resistant homes. Unlike wood, steel does not warp, rot, or weaken when exposed to moisture. The material can handle both compressive and tensile forces, making it well-suited for resisting strong winds.

A light steel frame distributes loads evenly, reducing the risk of structural failure during a hurricane. Bolted and welded connections add to its strength, especially when paired with reinforced foundations. Galvanized steel also resists corrosion, which is important in coastal areas.

Builders often combine light steel framing with concrete or masonry walls for added stability. While steel can increase upfront costs, it reduces long-term maintenance and provides a level of durability that lighter materials cannot match.

Structural Insulated Panels (SIPs)

Structural insulated panels, or SIPs, are prefabricated building elements made of rigid foam insulation sandwiched between two structural boards, often oriented strand board (OSB). SIPs provide both insulation and strength in one system.

When properly installed, SIPs create tight building envelopes that resist air and water infiltration. Their solid-core design makes them stronger than traditional wood framing, offering better resistance to wind pressure. SIPs also reduce thermal bridging, improving energy efficiency.

SIPs can be used for walls, roofs, and floors. They must be anchored securely to the foundation and connected with reinforced joints to perform well in hurricane conditions. While they may require specialized labor, their combination of strength and efficiency appeals to many homeowners in storm-prone regions.

Impact-Resistant Glass

Impact-resistant glass plays a critical role in protecting homes from flying debris. Unlike standard glass, it uses laminated layers that hold together when shattered, preventing dangerous openings during storms. This reduces the risk of sudden pressure changes that can damage roofs and walls.

In addition to safety, impact-resistant glass improves energy efficiency and provides year-round security against break-ins. While more costly than standard windows, it eliminates the need for shutters and adds long-term value to the home.

Hurricane-Proof Prefab and Modular Homes

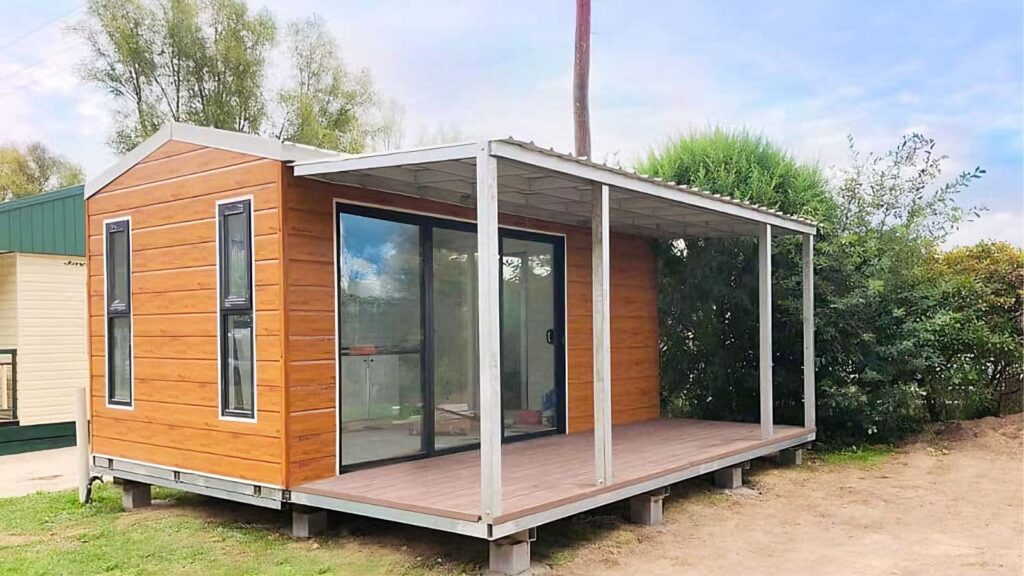

Hurricane-proof prefab and modular homes combine engineered strength with efficient construction. They use durable materials, tested designs, and controlled building methods to reduce risks from high winds, heavy rain, and flying debris.

Advantages of Prefabricated Homes

Prefabricated homes are built in factories under controlled conditions. This process reduces errors caused by weather delays and ensures consistent quality. For hurricane-prone regions, this means stronger joints, tighter seals, and better material protection before assembly.

Many prefab homes use light steel frames, concrete panels, or structural insulated panels (SIPs). These materials resist warping, water damage, and wind pressure better than traditional wood framing.

Another benefit is speed. Factory-built sections allow faster assembly on-site, which can be critical after a storm when rebuilding quickly is necessary. Prefab homes also often cost less than custom builds, while still meeting strict hurricane standards.

Energy efficiency is another advantage. Many hurricane-resistant prefab homes integrate insulation, airtight construction, and eco-friendly materials that reduce long-term energy costs.

Modular vs. Prefab: Key Differences

The terms modular and prefab are related but not the same. Prefab is a broad category that includes any home built in parts off-site, while modular homes are a specific type where entire sections, or modules, are built in a factory and then assembled like blocks on the foundation.

Modular homes often look identical to site-built houses once completed. They can be designed for multi-story layouts and customized floor plans. Because they are transported in large sections, they must meet strict codes for structural integrity, which adds strength in hurricane zones.

Prefab homes can also include panelized systems (wall and roof panels shipped flat) or kit homes where materials are pre-cut. These options may offer more flexibility in shipping and design but require more assembly on-site.

In hurricane-prone areas, modular homes usually provide the highest level of tested durability, while panelized prefab homes can be more affordable and quicker to ship.

Hurricane-Resistant Prefab Home Design

Hurricane-resistant prefab homes include specific design features that improve safety. Elevated foundations protect against storm surge and flooding. Impact-resistant windows and doors prevent breakage from flying debris. Reinforced roofs with multiple slopes or circular shapes reduce wind uplift.

Materials play a major role. Steel frames, concrete walls, and SIPs provide strong resistance to wind and water. Homes built with these materials are less likely to suffer structural failure compared to traditional wood.

Some manufacturers also design homes with aerodynamic shapes, such as round or hexagonal layouts, which allow wind to flow around the structure instead of pushing against flat walls.

Additional features often include hurricane shutters, watertight seals, and anchoring systems that secure the home to its foundation. These details work together to ensure that prefabricated and modular homes can withstand Category 4 or even Category 5 hurricane conditions when built to code.

Specialized Designs of Hurricane Ready Home

Engineers and builders use proven structural methods to reduce wind pressure, prevent flooding, and keep buildings stable during severe storms. These design strategies focus on shape, elevation, and support systems that improve safety without limiting functionality.

Pedestal and Stilt Houses

Pedestal and stilt houses raise the main living space above expected flood levels. This design reduces the risk of water damage during storm surges and allows water to flow beneath the structure instead of pushing against walls.

Pedestal homes often use a central reinforced column that supports the house. This provides stability while keeping the footprint small. In coastal areas, stilt systems with multiple support posts distribute weight evenly and reduce the chance of collapse.

Materials such as reinforced concrete and steel are common for these supports. They resist corrosion and withstand high water pressure. Builders also design open foundations to prevent debris from collecting under the home, which lowers the risk of structural failure during flooding.

Circular and Multi-Sided Designs

Hurricane-resistant houses often use circular or polygonal shapes. A round or multi-sided structure allows wind to move around the building instead of hitting flat walls directly. This reduces pressure on any single side and lowers the chance of roof or wall failure.

These designs also use reinforced roof connections and continuous load paths. This means the roof, walls, and foundation are tied together, so the force of the wind transfers through the entire structure instead of one weak point.

Elevated Foundations

Elevated foundations keep the base of the house above storm surge and flood levels. Builders often use concrete piers, piles, or reinforced slabs to raise the structure several feet higher than code requirements.

In flood-prone regions, this elevation is critical. It prevents water from entering living areas and protects mechanical systems like electrical panels and HVAC units.

Some communities combine elevated foundations with storm-resistant stairways, ramps, and lift systems. This ensures accessibility while maintaining safety standards. By lifting the structure and securing essential systems, elevated foundations provide one of the most reliable defenses against hurricane damage.