Light gauge steel construction has become a trusted method in modern building projects, offering precision, speed, and durability that traditional materials often cannot match. It uses thin, cold-formed steel sections to create strong yet lightweight structural frameworks for residential, commercial, and industrial buildings.

As construction demands continue to evolve, light gauge steel stands out as a material that balances strength with sustainability. From framing systems to full building applications, it provides a reliable foundation for projects that require both performance and adaptability.

What Is Light Gauge Steel Construction?

Light gauge steel construction is valued for its precision, durability, and flexibility in both residential and commercial projects. The method has grown in popularity as an alternative to wood and heavy steel because it balances strength, cost, and speed of construction.

Light gauge steel is made by cold-forming thin sheets of steel at room temperature into shapes that serve as studs, joists, and beams for walls, floors, and roofs.

This type of construction is lightweight but strong. A typical steel thickness ranges from 1 mm to 3 mm, making it easy to transport and assemble without heavy machinery. Despite its light weight, it offers high load-bearing capacity and dimensional stability.

Core Materials and Manufacturing Process

Light gauge steel relies on thin sheets of cold formed steel that are shaped through controlled factory methods. Protective coatings and standardized profiles ensure strength, durability, and consistent performance across different types of building applications.

Cold Formed Steel Production

Cold formed steel is made by rolling thin sheets of steel at room temperature. Unlike hot rolled steel, this process does not involve heating the material above its melting point. Instead, it uses mechanical force to bend and shape the steel into precise dimensions.

The sheets typically range between 18 and 25 gauge in thickness. They are cut and formed into specific profiles such as studs, tracks, and joists. This controlled process results in uniform strength and predictable performance.

Because the steel is shaped without heat, it maintains tighter tolerances. This makes it well suited for prefabricated frames and modular construction where accuracy is critical.

Galvanization and Corrosion Protection

To protect light gauge steel from rust, manufacturers use a zinc coating through galvanization. This coating acts as a barrier between the steel and moisture, which greatly extends the lifespan of the material.

The most common method is hot-dip galvanization, where steel sheets are submerged in molten zinc. Another method is electro-galvanization, which applies zinc using an electrical current. Both processes improve resistance to corrosion but differ in coating thickness and cost.

Key benefits of galvanization include:

- Reduced maintenance needs

- Longer service life in humid or coastal environments

- Consistent surface quality for finishing and assembly

Without this protective layer, thin steel sections would corrode quickly, especially in exposed or damp conditions.

Light Gauge Steel Framing Systems

Light gauge steel framing relies on cold-formed steel members that are shaped into standardized profiles and assembled into a framework. These systems include different components that serve specific roles and can be designed as either load-bearing or non-load-bearing depending on the structural needs of the building.

Steel Framing Components

Light gauge steel members are typically formed into C-sections, U-sections, and tracks. C-sections are used for studs, joists, and rafters, while U-sections or channels act as top and bottom plates. These shapes are manufactured with punched holes to allow for wiring, plumbing, and bracing without additional drilling.

A typical system includes:

- Wall studs for vertical support

- Joists for floors and ceilings

- Trusses for roof framing

- Tracks and channels for alignment and load transfer

- Accessories such as angles, straps, and plates for reinforcement

The steel is galvanized with zinc, aluminum, or a mix of both to prevent corrosion. Thickness varies by gauge, with heavier gauges used for load-bearing members. Connections are made with self-drilling screws, bolts, or welding in prefabricated panels.

This combination of standardized shapes, protective coatings, and reliable fastening methods makes the framing system both durable and adaptable to different building designs.

Structural vs Non-Structural Framing

Structural framing carries vertical and lateral loads. These members form the skeletal framework of walls, floors, and roofs. Load-bearing studs, joists, and trusses are designed to transfer forces safely to the foundation. Heavier gauges, such as 12 to 16, are common for these applications due to higher strength requirements.

Non-structural framing does not support loads beyond its own weight. It is often used for interior partitions, wall cladding, or ceiling framing. These members are lighter, typically ranging from 18 to 25 gauge, and allow easier modification during renovations.

The distinction between the two is critical. Structural members must meet strict engineering standards, while non-structural framing focuses on flexibility, speed, and cost efficiency. Both types are essential in modern light gauge steel construction, but they serve different roles within the same system.

Applications in Building Construction

Light gauge steel construction supports a wide range of building types by combining strength, durability, and adaptability. It is commonly used in housing, large-scale facilities, and both interior and exterior finishing systems.

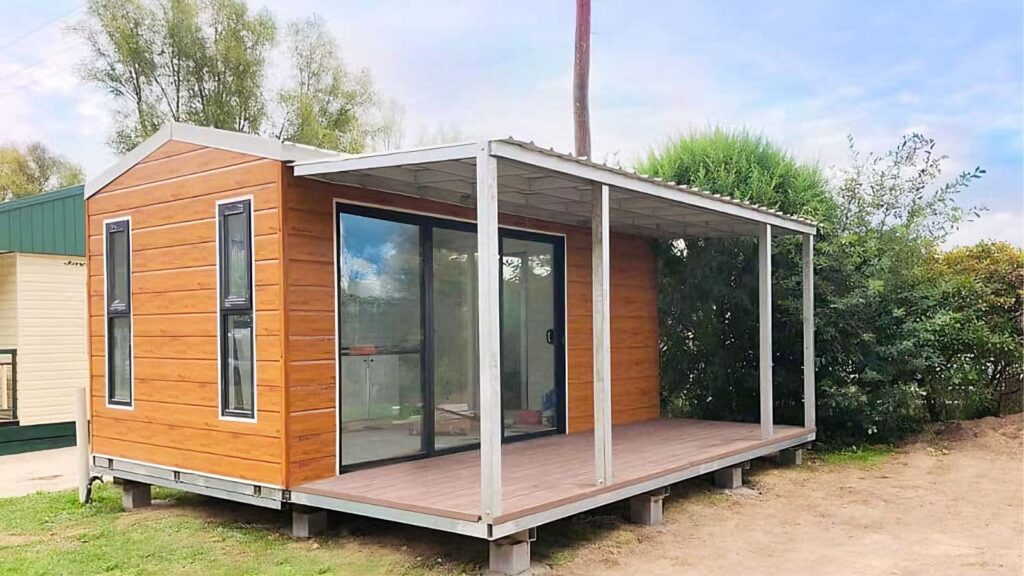

Residential Structures

Light gauge steel framing is widely used in single-family homes, townhouses, and apartment buildings. Its light weight reduces foundation loads, making it suitable for sites with soil limitations.

Builders often choose steel for its fire resistance, pest protection, and moisture resistance, which extend building life. These qualities are especially valuable in humid, termite-prone, or high-risk fire zones.

Commercial and Industrial Uses

In commercial and industrial projects, light gauge steel is used for warehouses, retail centers, schools, and healthcare facilities. Its ability to span up to 12 meters without intermediate supports makes it well-suited for large, open spaces.

Portal frames and truss systems allow column-free interiors, which are essential for manufacturing floors and storage areas. The lightweight nature of cold-formed steel also reduces transportation and handling costs.

Fast installation is another advantage in this sector. Prefabricated components can be delivered to site with precise dimensions, minimizing downtime and ensuring predictable project schedules.

Steel’s non-combustible properties also meet fire safety standards required in public and high-occupancy buildings. Combined with corrosion protection such as hot-dip galvanizing, these structures achieve long service life with minimal upkeep.

Construction Process and Techniques

Light gauge steel construction depends on precise planning, careful site preparation, and accurate installation methods. The process also requires coordination with building systems such as plumbing and electrical to ensure structural efficiency and long-term durability.

Planning and Design Considerations

The process begins with defining the building’s purpose, whether residential, commercial, or industrial. Architects and engineers create detailed drawings that specify the size, spacing, and type of steel members. These plans account for load requirements, fire protection, and insulation needs.

Computer-aided design (CAD) software is often used to model the structure. This allows designers to test different layouts and identify potential issues before construction begins.

Key factors include:

- Span lengths for floors and roofs

- Wall thickness for load-bearing and non-load-bearing sections

- Integration points for plumbing, electrical, and HVAC

Accurate design reduces waste, shortens construction time, and ensures that prefabricated parts fit correctly during assembly.

Site Preparation and Foundation

Site preparation starts with clearing debris, leveling the ground, and marking the building layout. Because light gauge steel framing is lightweight, the foundation does not need to be as heavy as for concrete or masonry structures.

Common foundation types include:

- Shallow strip footings for smaller buildings

- Slab-on-grade foundations for residential or commercial projects

- Pile foundations when soil conditions are poor

Anchor bolts are set into the foundation to secure the steel frame. Proper alignment is critical because even small errors can affect the fit of prefabricated components. Drainage and moisture control are also addressed at this stage to prevent long-term structural issues.

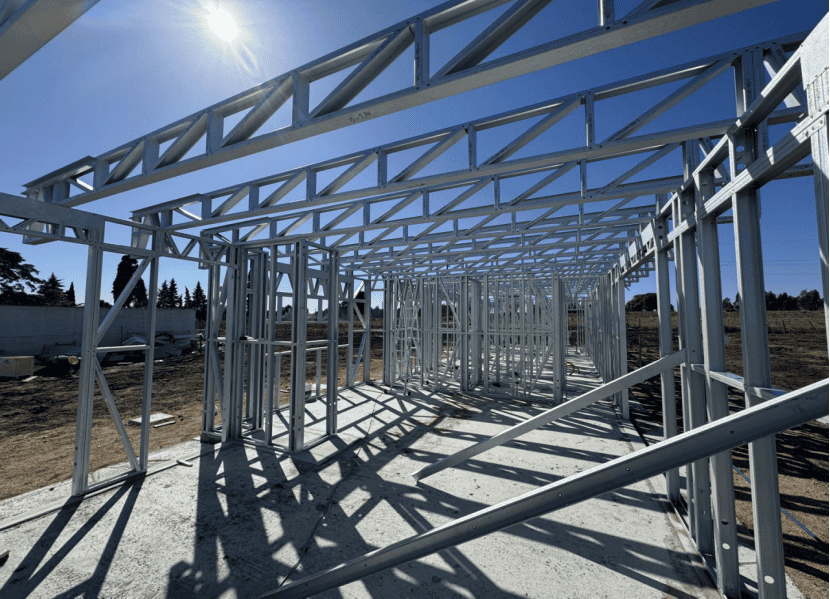

Frame Assembly and Installation

The frame is built using cold-formed steel sections such as studs, tracks, and joists. These components are either prefabricated into panels or assembled on-site. Prefabrication helps save time and ensures consistent quality.

Installation follows a sequence:

- Wall panels are positioned and secured to the foundation.

- Floor joists and decking are added to create load-bearing levels.

- Roof trusses are installed to complete the structural skeleton.

Connections are typically made using screws, bolts, or welds. Bracing is added to resist lateral loads from wind or seismic activity. The precision of steel components allows for straight walls, accurate openings, and easy alignment with other building systems.

Integration of Plumbing and Electrical Systems

Plumbing and electrical systems are installed once the frame is in place. Light gauge steel studs often come with pre-punched holes, which allow pipes and conduits to pass through without additional cutting.

For plumbing, plastic or copper pipes are commonly used. Care is taken to insulate them properly to prevent condensation or noise transfer through the steel frame. Special grommets or sleeves protect pipes from sharp steel edges.

Electrical wiring is routed through the same openings. Electricians use protective bushings to prevent wire damage. Junction boxes are mounted to steel studs using brackets or clips.

This integration stage requires coordination between trades to avoid conflicts. Proper planning ensures that plumbing and electrical systems fit neatly within the framing without weakening the structure.

Advantages of Light Gauge Steel Construction

Light gauge steel, also known as cold formed steel, provides a combination of strength, flexibility, and efficiency that makes it a practical choice for many building projects. At the same time, it comes with specific challenges that require careful planning and additional measures.

Strength, Durability, and Fire Resistance

Light gauge steel framing offers high strength relative to its weight. This allows builders to design longer spans and larger open spaces without relying on heavy structural supports. It also reduces the need for thick foundations, since the material is lighter than concrete or timber.

Durability is another key benefit. Steel does not rot, warp, or shrink, and it resists termites and other pests that damage wood. When galvanized or coated with zinc or aluminum, it gains long-term protection against corrosion, which is important in humid or marine environments.

In terms of fire performance, steel is non-combustible and does not add fuel to a fire. However, cold formed steel loses strength when exposed to high heat. To address this, builders often apply fire-rated sheathing or protective coatings to maintain structural stability during a fire.

Cost Efficiency and Sustainability

Prefabrication of light gauge steel components in factories reduces on-site labor and speeds up construction. Since members are lightweight, handling and installation require less equipment and time, which lowers labor costs. Smaller foundations also help reduce material expenses.

From a sustainability standpoint, steel is fully recyclable without losing quality. Construction waste is minimal because components are manufactured to precise dimensions. This makes it easier to meet green building standards and reduce environmental impact.

Energy efficiency can be improved with proper insulation. Although steel itself conducts heat, adding thermal breaks and insulation layers helps control energy loss, making buildings more efficient to heat and cool. This balance of cost savings and environmental benefits makes cold formed steel an attractive option for both residential and commercial projects.