The DEEPBLUE SMARTHOUSE computer-aided design (CAD) system offers an ideal solution for optimizing the design and construction of modular buildings, whether assembled on-site or prefabricated offsite. This advanced system delivers cost-effective, highly accurate results while significantly reducing project timelines, and its scalable manufacturing process allows for rapid, economical replication of modules, ensuring efficiency across multiple projects.

But what exactly is prefab CAD and what other features does it have? Let’s find out at Deepblue Smarthouse!

What is Prefab CAD

Prefab CAD stands for Computer-Aided Design used specifically in prefabricated construction. It helps designers create digital models for building parts that are made in factories and then assembled on site.

Core Concepts

Prefab CAD uses digital tools to design parts of buildings that are manufactured off-site. These parts, or modules, are created as detailed 3D models. Every detail, such as windows, doors, and even electrical wiring, is built into the digital plan.

The key advantage is accuracy. Since each component is planned carefully in CAD software, factories can produce modules with less error. Digital models help avoid mistakes and allow for easy changes if needed.

Other important concepts include:

- Detailed measurements for every building piece

- Built-in checks for aligning plumbing, electrical, and structural systems

- Virtual walk-throughs to spot design issues early

This process leads to faster assembly when modules arrive at the building site.

Difference Between Prefab and Traditional CAD

Traditional CAD is used for buildings that are constructed completely on-site, one step at a time. It typically focuses on supporting manual building methods.

Prefab CAD, on the other hand, is designed for manufacturing building parts in controlled factory settings. The software includes functions for dividing a building into modules, designing them for transport, and making sure they fit together during on-site assembly.

A key difference is the level of integration. Prefab CAD often includes layouts for electrical, plumbing, and HVAC systems directly in the model. This information is needed for factory production. In traditional CAD, these details are planned but may be adjusted during on-site construction.

Benefits and Challenges

Prefab CAD, or Computer-Aided Design used in prefabrication, offers both significant advantages and some real obstacles for architects. The technology can transform accuracy, speed, and workflow in building projects, but also presents challenges related to integration and planning.

Quality Control and Precision

Prefab CAD improves the quality of building components by allowing detailed design and modeling before anything is manufactured. Errors can be caught on screen, not on-site, which reduces wasted materials and costly fixes. Designs can also be duplicated with high levels of consistency, making mass production of parts more reliable.

In controlled factory settings, these digital plans help streamline machines and workers. This ensures that each piece meets strict standards and reduces variation from one batch to another.

Challenges arise with compatibility between different CAD software or when converting designs from digital files to physical materials. If information is not properly coordinated, mistakes can pass through to manufacturing or assembly.

Efficiency and Project Timelines

Using CAD in prefab projects often shortens design and construction timelines. Digital planning speeds up the drawing process and changes can be made quickly and shared with all team members in real time.

Project schedules become more predictable since weather delays are reduced and pieces arrive ready for installation. On-site labor is also minimized, saving time required after deliveries.

However, upfront planning is essential. Any delays or errors in the early CAD stages can cause significant project setbacks. Prefab CAD also requires skilled staff familiar with both design software and factory processes.

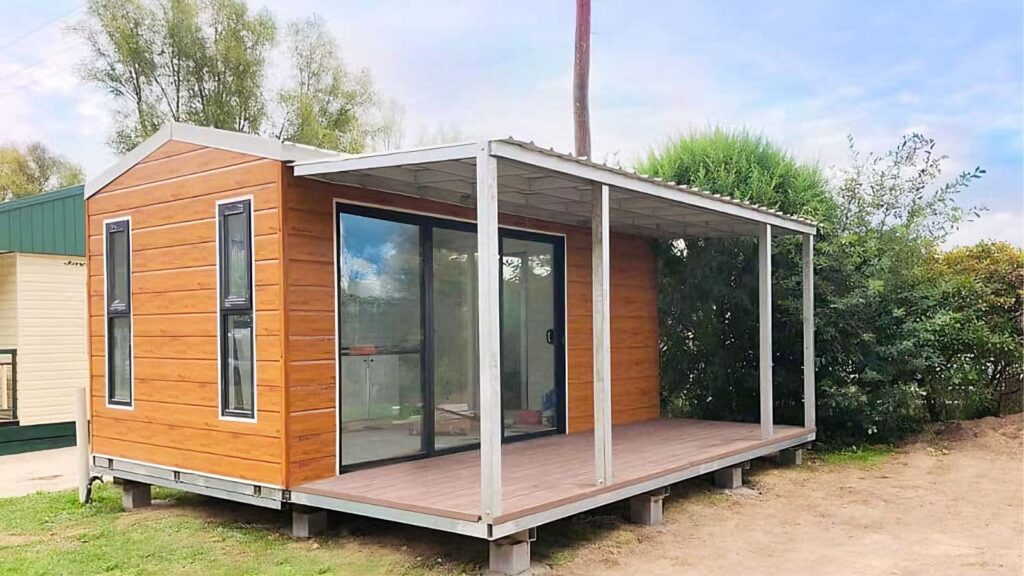

Showcase of a Deep Blue Smart House project

The skilled designers at Deepbluehome take pride in their capacity to fully utilize the CAD system, and here is one of the prime examples of Deepblue Smarthouse project.