Light Steel Frame (LSF) Solutions: Four Global Project Case Studies

In the global construction industry, Light Steel Frame (LSF) buildings have emerged as a practical alternative, offering adaptability to diverse geographical conditions, functional requirements, and project constraints. LSF structures utilize prefabricated cold-formed steel components, combining efficient construction processes, cost predictability, and durability. These attributes make them suitable for projects including hotels, employee dormitories, villas, and government housing across the US, Australia (AU), EU, and remote island regions. Below are four LSF project examples, highlighting how specific challenges were addressed to deliver compliant, performance-oriented results.

1. Island Hotel | Caribbean Islands | Wind & Corrosion Considerations

An 80-room boutique hotel project in the Caribbean Islands addressed two regional conditions: hurricane wind loads (up to 260 km/h) and saltwater exposure. The client required a timely build to align with the tourist season, within a defined budget. Hot-dip galvanized LSF components (zinc layer thickness ≥275g/㎡) were used for corrosion resistance, and the frame design was optimized via finite element analysis to support wind load requirements. Prefabricated components were shipped in modular units, reducing on-site labor by 40%. The 2,800㎡ hotel was completed in 16 weeks (30% faster than conventional concrete construction), 12% under budget, and met Caribbean Building Code (CBC) standards for wind and corrosion resistance.

2. Employee Dormitory | Texas, US | Time & Budget Constraints

For a manufacturing client in Texas, a 6-story, 3,500㎡ employee dormitory was designed to house 200 workers, with a 20-week completion schedule and a defined budget. The project site was in a suburban location with limited local labor availability. A panelized LSF system was adopted, with 95% of components prefabricated in the factory. BIM technology was used to coordinate design and reduce on-site adjustments (tolerance ±2mm). Local labor was utilized for assembly, and component deliveries were sequenced to minimize site disruptions. The dormitory was completed in 18 weeks, 15% below budget, and complied with OSHA safety standards and Texas Accessibility Standards (TAS) for residential buildings.

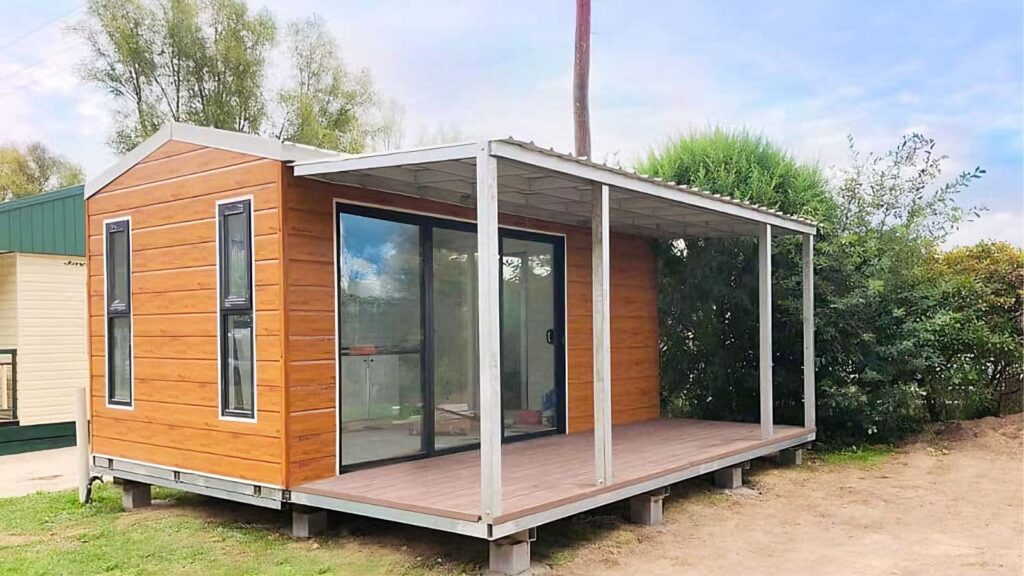

3. Luxury Villa | Queensland, AU | Corrosion & Compliance Considerations

A 450㎡ villa in Queensland required LSF construction suitable for coastal humidity, termite exposure, and Australian building regulations (NCC 2022). The client prioritized sustainability and low maintenance. Recycled LSF components (85% recyclable steel) were used, and a five-layer composite insulation wall system was installed to support energy efficiency (U-value of 0.18 W/(㎡·K)). Secondary corrosion treatment was applied to all cut steel sections. The villa was completed in 8 weeks, 8% under budget, and is termite-resistant, fire-resistant (120-minute rating), and compliant with NCC 2022 energy and safety standards. Maintenance requirements are projected to be low over its 50-year design life.

4. Government Housing | Greenwich, EU | Space & Environmental Considerations

A project in Greenwich, UK, involved 48 units of government social housing on a constrained urban site adjacent to a train line and residential areas. Site access was limited, and the project was subject to EU environmental regulations (EPBD 2021) and a fixed budget. A panelized LSF system was selected to reduce on-site waste (60% less than traditional construction) and minimize concrete deliveries, lowering carbon emissions. Compact component design facilitated storage and assembly in the confined site. The 5,200㎡ housing complex was completed in 24 weeks, 10% under budget, met EPBD 2021 energy efficiency targets (70% reduction in carbon footprint), and complied with UK Building Regulations for social housing.

These examples illustrate the adaptability of LSF construction across varied regional and project-specific conditions. From island locations with high wind exposure to urban sites in the EU, LSF has demonstrated efficient construction timelines, controlled costs, and regulatory compliance. Whether for hotels, dormitories, villas, or government housing, LSF solutions can be tailored to specific project locations and requirements.