In recent years, there has been a new trend in the hospitality industry: The modular hotel, a paradigm offering a faster, smarter, and more sustainable path from concept to completion.

This article delves into the world of modern luxury modular building, exploring the key features that define these spaces and how they contribute to a new standard in the hospitality industry.

Offsite Modular Construction Advantage

Compared to traditional methods of constructing buildings with raw materials like wood, concrete and rebar, modular construction boasts a unique list of advantages.

Defining “Modular” in Modular Hotel Construction

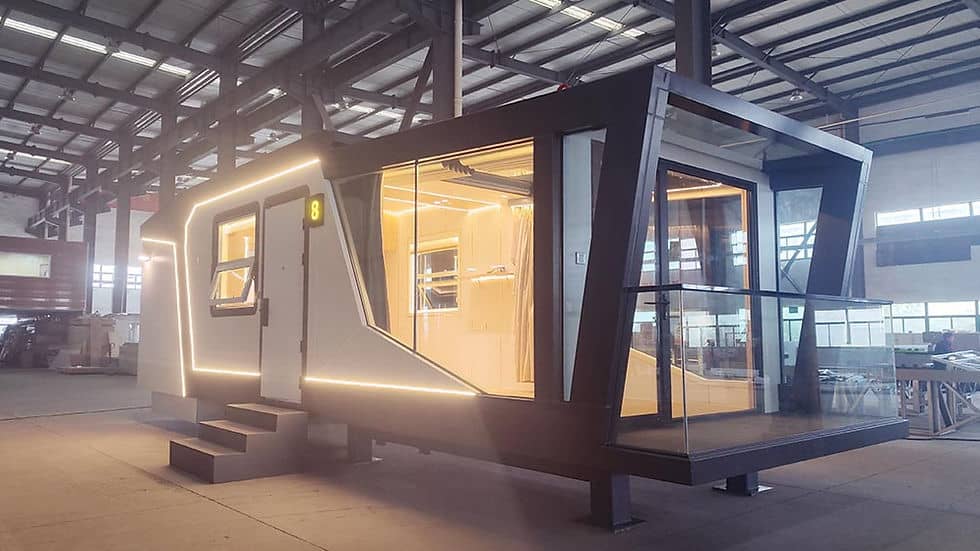

At the heart of this revolution is modular construction, a process where individual modular hotel rooms, or pod-like structures, are fabricated off-site in a controlled factory environment. This approach treats each room as a self-contained volume, which is constructed, insulated, wired, and plumbed to a high degree of completion on a factory assembly line. Walls are painted, flooring is laid, and even furniture and amenities like televions are installed before the unit ever leaves the facility.

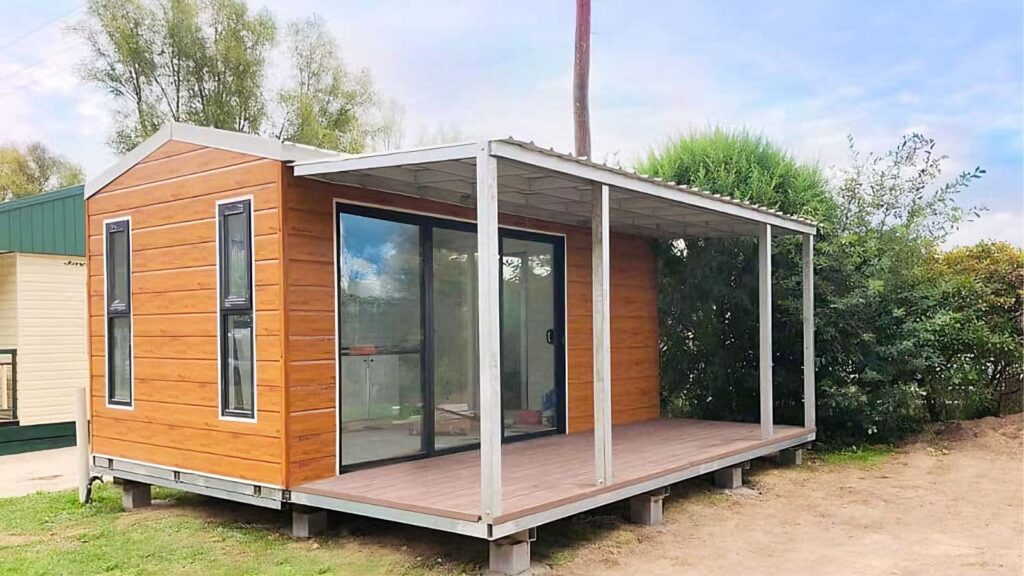

These fully finished modular units are then transported to the construction site for final assembly onto a pre-prepared foundation. This method stands in stark contrast to traditional building methods, where weather, labor shortages, and logistical complexities can derail a project’s timeline and budget. Essentially, modular construction shifts the majority of the building process from a chaotic, weather-dependent job site to an orderly, efficient manufacturing plant, redefining the very sequence of how a building comes together.

Accelerated Timelines and Financial Benefits

The decision to pursue modular construction for the hospitality industry is rooted in a compelling value consideration. The parallel building process—where site foundation work happens simultaneously with room construction in the factory—can slash the overall project timeline by up to 50%. This concurrency eliminates the sequential delays common in traditional projects, where interior work cannot begin until the exterior shell is fully sealed against the elements.

This faster turnaround means a quicker return on investment for owners and the ability to open for business sooner. A hotel that opens months ahead of schedule can start generating revenue during the peak season, significantly impacting profitability. Furthermore, the compressed timeline reduces financing costs, as construction loans are needed for a shorter period. This financial efficiency makes modular an increasingly attractive option for developers looking to mitigate risk and maximize their investment in a competitive market.

Enhanced Quality, Efficiency, and Sustainability

Furthermore, the controlled conditions of factory production allow for superior quality control. Every fixture, from the gas water heater system to the smart home systems, is installed with precision by specialized teams, minimizing errors and ensuring every guest room meets exact specifications. The building materials are also protected from rain, sun, and theft, which prevents damage, warping, and mold growth that can plague traditional sites, leading to a more durable and consistent final product.

This precision also leads to significant cost savings and less waste than traditional methods, as materials are optimized through bulk purchasing and computer-aided design, with leftovers often reused on subsequent modules. This environmentally friendly approach aligns with the growing emphasis on sustainability in the hospitality project lifecycle. There is also the potential to reuse modules in the future and integrate energy-efficient systems, such as advanced insulation and low-flow plumbing, from the outset, reducing the hotel’s long-term carbon footprint and operational expenses.

A Deep Dive into the Luxury Modular Hotel

So, what does a modern luxury modular hotel room actually look and feel like? Far from being a sterile box, it is a testament to architectural innovation and guest-centric design, offering a level of customization and comfort that is truly remarkable.

1. Climate Control and Comfort: Advanced HVAC Systems

A cornerstone of guest comfort is the indoor environment. Modern luxury units come equipped with advanced heating, ventilation, and air conditioning (HVAC) systems designed for optimal performance.

These systems are installed during the room construction phase in the factory, and serve as an integrated function of the unit. Whether designed for natural ventilation in temperate climates or robust heating and cooling for more extreme environments, the HVAC system ensures a consistent and comfortable atmosphere. This focus on energy-efficient climate control is a key part of the sustainability promise and guest comfort of modular builds.

2. The Intelligent Room: Smart Home and Smart Hotel Systems

Seamless technology integration is a clear sign of the modern experience. These units feature state-of-the-art smart home systems. It combines automation, voice control, and sensors to create a highly personalized stay.

Guests can control lighting, temperature, and other aspects of the house from a single interface, often their own smartphone or an in-room tablet. The building system is designed with sensors that detect occupancy, automatically adjusting settings to save energy when the room is empty and creating a welcoming environment upon return. This modular technology not only enhances the guest experience but also streamlines operations for management.

3. Blurring the Lines Between Interior and Exterior

One of the most striking architectural features of these units is their use of glass to connect guests with the outside world. Full-size windows are engineered to offer breathtaking 270-degree panoramic views, making guests feel immersed in their surroundings, whether in a bustling city or a serene natural landscape.

Adding to this connection is the innovative inclusion of skylights for stargazing. This feature, a luxury often difficult to implement in traditional buildings due to structural complexities, can be seamlessly incorporated into the module during fabrication. Imagine lying in bed and looking up at the night sky—a unique selling point that creates a memorable boutique hotel feel. Solar shading elements can also be integrated into the façade or window design to manage heat gain and glare naturally.

4. The Sanctuary Within: Bespoke Bathrooms and Amenities

The bathroom is no longer just a utilitarian space. Many projects now utilize prefabricated bathrooms, or prefab pods, which are entire bathroom units manufactured off-site. This approach ensures impeccable waterproofing, perfect tile work, and the precise installation of all fixtures, including the gas water heater system for reliable hot water.

Beyond the bathroom, developers can furnish the room to a very high-quality standard, integrating music systems and other amenity ties that cater to the modern traveler’s desires. The ability to create unique and compelling interiors is a key advantage, allowing a motel, a resort, or an urban hotel to express its distinct brand identity.

Conclusion

As modular technology continues to evolve and more hotel builders and major brands adopt these modular solutions, we can expect to see even more innovative and breathtaking designs. The future of hospitality is being built in factories, and it is a future of luxury, efficiency, and endless possibility. The modular hotel has arrived, and it is here to redefine our very understanding of a place to stay.