Light steel frame construction has a much longer history than most people realize. It began in the 19th century when builders started using cold-formed steel shapes in England and the United States for innovative projects, taking advantage of steel’s strength, light weight, and durability. Over time, advances in mass steel production and better design standards made it possible for steel framing to replace traditional materials in many building types.

Origins and Evolution of Light Steel Frame Construction

Light steel frame construction has roots in early experiments with steel as a building material. The development of new technologies and design standards allowed steel framing to become widely used, especially as builders found advantages over traditional materials like timber and masonry.

Early Applications in Building Industry

The first uses of cold-formed, or light gauge, steel framing began in the mid-19th century. Builders in the United States and England tried using steel for building frames as early as the 1850s.

During the California Gold Rush in 1849, “portable iron houses” became an option for quick and fireproof shelters. Most early uses were limited because few design standards existed and steel was not yet widely available.

In early 20th century, around the 1930s, steel-framed houses were showcased at major events like the Chicago World’s Fair. These efforts promoted the idea of prefabricated steel homes but did not yet lead to mass market adoption. Builders saw steel as useful for its strength and ease of assembly but faced barriers with cost, limited knowledge, and lack of building codes.

Advancements in Cold-Formed Steel Technology

The introduction of cold-forming technology was a turning point. Cold-formed steel allows steel sheets to be shaped into strong and lightweight elements using rolls at room temperature.

This progress gave rise to a standard for light gauge steel framing—ideal for both interior and exterior walls. Builders began using cold-formed steel due to its high strength-to-weight ratio, fire resistance, and versatility. This construction method utilized cold-formed steel (CFS) framing, which revolutionized the building material landscape. After World War II, demand for affordable and quick housing increased, accelerating the use of light steel framing. Companies like Lustron built thousands of steel-framed homes with factory-made panels.

During the 1950s and 1960s, the steel framing industry association began to promote the use of cold-formed steel structural systems, leading to widespread adoption in commercial buildings. These structures often featured curtain walls and interior walls constructed with light gauge steel, providing a robust alternative to traditional wood framing.

Light steel frames have become a staple in the construction industry, particularly for projects that include framing with brick veneer. The versatility of steel made it possible to create shaft walls and other structural elements that meet the demands of modern architecture.

As the construction material landscape evolves, the integration of cold-formed steel continues to shape the future of building practices, providing a reliable and efficient solution for both residential and commercial applications.

Influence of American Iron and Steel Institute (AISI)

The American Iron and Steel Institute (AISI) played a central role in establishing standards for light steel frame construction. In 1939, AISI began sponsoring research focused on cold-formed steel at Cornell University, under the leadership of George Winter.

AISI published the first design specification for light gauge steel structural members in 1946. These guidelines covered material thickness, yield strength, and methods for designing connections. Later revisions reduced safety factors and adapted standards to match broader industry practices.

AISI’s efforts helped shape building codes, provide engineers with standard references, and support the growth of the Steel Stud Manufacturers Association. Today, AISI continues to update specifications, making cold-formed steel framing safer and easier to use in all types of construction.

Technological Innovations and Standardization

Modern light steel frame construction relies on technological improvements and standardized practices. Advancements in prefabrication, materials, construction codes, hardware, and energy standards have shaped the field.

Adoption of Prefabrication Methods

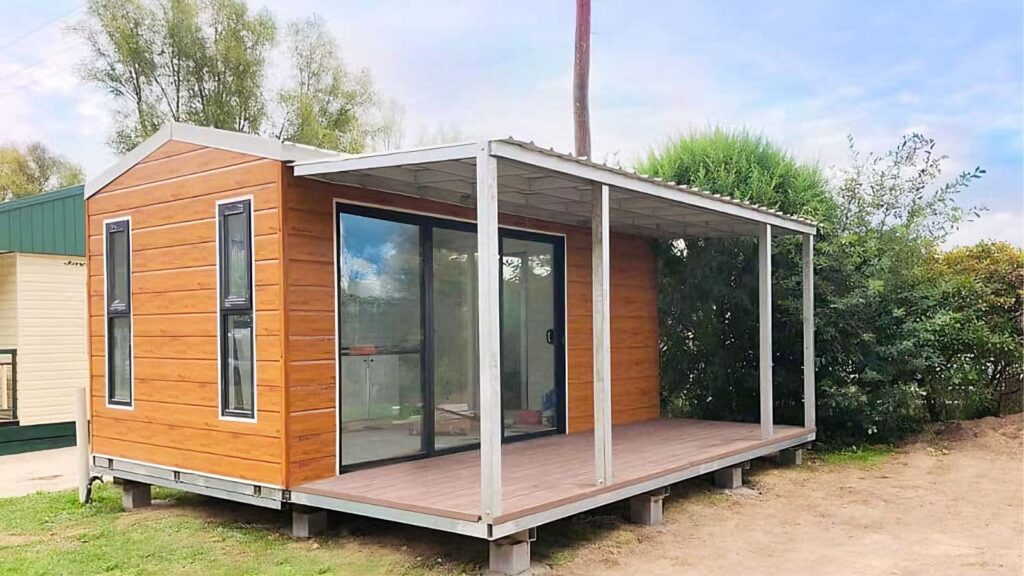

Prefabrication has transformed how light steel frames are used in buildings. Components like walls and floors are made in factories, then delivered to construction sites ready for assembly. This process saves time, cuts down on waste, and makes the build more predictable.

Builders benefit from higher quality control because the environment in factories is carefully managed. Designs are checked and repeated with precision, reducing human errors. Weather delays are less of a problem since much of the work is done indoors.

A key effect of prefabrication is faster project completion. Projects that once took months using traditional methods can now be finished in weeks. The predictability and speed are important for developers and clients looking for cost-effective solutions.

Development of Steel Studs and Joists

Steel studs and joists are the backbone of light steel frame construction. Unlike traditional wooden framing, steel components are formed by bending thin steel sheets, usually through a process called cold-forming. This process gives steel studs their light weight and high strength.

Steel studs come in standard sizes, which makes design and construction easier. They are not affected by termites, rot, or warping like wood. Builders appreciate that steel joists offer strong support for floors and roofs, especially in multi-story buildings.

Advancements in Energy Efficiency

Current light steel frame systems must meet energy efficiency requirements. Steel frames can conduct heat and cold, so special attention is given to insulation and thermal breaks.

Engineers use thermal break materials—often plastic or foam strips—between steel studs and wall surfaces. These materials limit heat transfer and help buildings stay warm in winter and cool in summer. Builders also use high-performance insulation products to improve energy ratings.

Compliance with energy efficiency and similar codes ensures that steel structures use energy wisely and reduce carbon emissions. The building envelope, windows, and insulation all contribute to meeting strict efficiency standards. This advances sustainability without giving up safety or strength.