Many people dream of buying land to build homes, but building a house quickly without overspending takes careful planning and smart choices. The cheapest and fastest way to build a house is to keep the design simple, use cost-effective materials, and rely on efficient construction methods.

With the right planning, smart material choices, and a clear approach to labor, anyone can find the cheapest way to build their dream home. Today at Deepblue Home, this article will help you avoid costly luxuries and find a way to save your money while building your own home.

Smart Planning for Affordable and Quick Construction

Careful preparation saves you money and time. Choosing where to build, how much to spend, and how to manage the process directly affects both cost and speed.

Setting a Realistic Budget

A clear budget prevents overspending and keeps the project moving. You should list all major expenses, including land, permits, foundation, materials, labor, and utilities. Adding a 15–20% contingency fund to your total build cost expectancy helps cover delays or price increases.

Breaking costs into categories makes tracking easier. For example:

| Category | Example Costs |

|---|---|

| Land | Purchase price, surveys, site prep |

| Materials | Lumber, panels, roofing, insulation |

| Labor | Skilled trades, subcontractors |

| Permits/Fees | Building permits, inspections |

| Utilities | Water, sewer, electrical connections |

Selecting the Right Location

The site chosen affects both upfront and long-term expenses. Land in rural areas may be cheaper to buy but could require costly utility hookups. In contrast, urban lots often cost more but already have water, sewer, and power connections.

Soil type and drainage also matter. Poor soil may require expensive foundation work, while sloped land can increase grading costs. A flat, stable site usually speeds up construction.

Access is another factor. Easy road access allows trucks to deliver prefabricated panels or modular units quickly. This reduces delays and saves on transportation fees.

Efficient Project Management

Good management ensures that each stage of construction happens on time. Creating a detailed schedule that lists tasks such as foundation work, shell assembly, utility installation, and interior finishes helps avoid downtime.

Some owners choose to manage the whole process by themselves, which might cost them more than just buying an existing house. After all, building a new home from the ground up is much harder than just putting up decorations, and the cost to build a house could soar if the owner has little experience in construction.

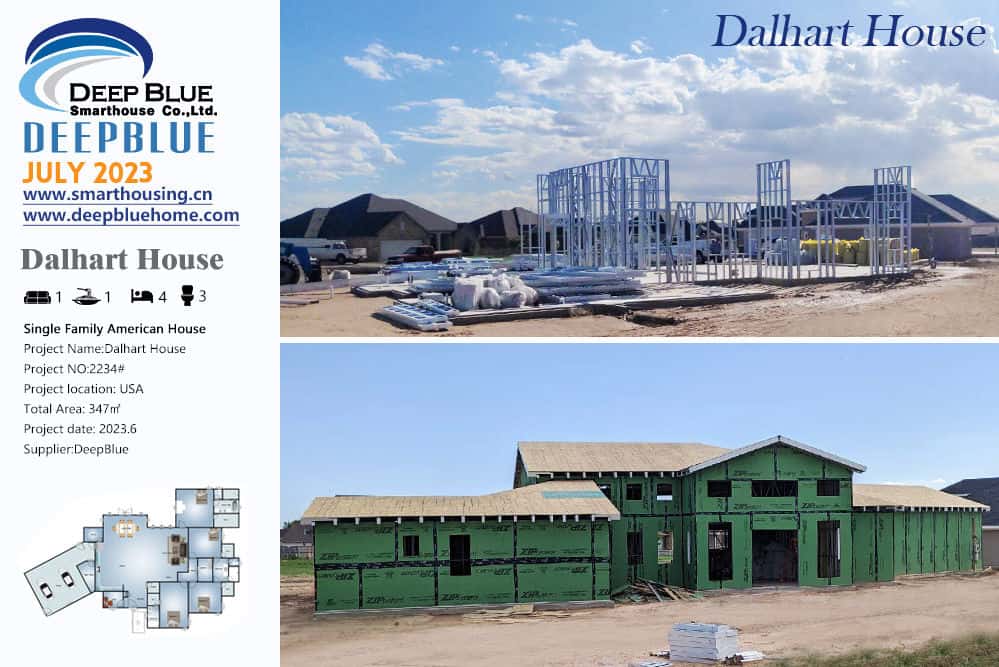

The demands for professional service are why home builders or construction contractors like Deepblue Home exist. Deepblue Home specializes in the design and construction of prefab homes, and provides one-stop solutions to housing developers, builders, owner-builders and so on. As a full-service provider, it also offers a wide range of services including design, engineering, manufacturing, and construction. These streamlined procedures greatly cut down the inconsistent pricing between different suppliers and time spent on finding them, leading to cheaper and faster construction.

Choosing Cost-Effective House Designs

Selecting the right design can ensure more leeway in a tight budget and speed up the building process. Small footprints, fewer structural complexities, and efficient layouts reduce both labor and material expenses while still providing comfortable living spaces.

Simple and Compact Floor Plans

Compact floor plans use space efficiently and cost less to build. A square or rectangular footprint requires fewer materials than complex shapes with extra corners or angles. Straightforward layouts also make it easier for builders to work quickly without specialized labor.

Open-concept designs combine the kitchen, dining, and living areas into one shared space. This reduces the need for extra walls and finishes, saving both money and time.

Smaller homes also allow for smaller foundations and roofs, which are two of the most expensive parts of construction. For example, a 1,000–1,200 square foot plan with two bedrooms and one bath can meet the needs of a small family while staying affordable.

Single-Story Versus Multi-Story

Single-story homes, such as ranch homes, often cost less to build per square foot because they avoid the need for staircases and complex structural supports. They also make maintenance easier since all systems and utilities are on one level.

However, single-story houses require a larger foundation and roof area, which can raise costs if land prices are high. Multi-story homes reduce the footprint, which means less land and foundation material, but they add expenses for stairs and stronger framing.

Colonial homes, which are often two stories, can be more cost-effective in areas where land is limited. Ranch homes, by contrast, are better suited for wide lots where foundation costs remain manageable.

Minimalist and Functional Layouts

A minimalist layout focuses on function over decoration. Fewer hallways, unnecessary rooms, or custom features keep costs down. Every square foot serves a purpose, which reduces wasted space and construction effort.

Straight lines and simple roof styles, such as gable or hip roofs, are less expensive than complex designs. Using standard-sized windows and doors avoids the higher costs of custom materials.

Functional layouts also make future maintenance easier. For example, grouping plumbing in one area—such as placing the kitchen, bathroom, and laundry close together—cuts down on pipe length and installation labor.

Builders often recommend layouts with flexible spaces. A single room can serve as a guest bedroom, office, or playroom, reducing the need for extra square footage. This approach balances affordability with livability.

Fast and Affordable Building Methods

Building quickly while keeping costs down often comes down to using efficient construction systems and reducing labor time. Factory-built components and streamlined assembly methods allow builders to save on both materials and on-site work.

Prefabricated House Construction

Prefabricated houses use factory-made sections that are delivered to the site and assembled, and are most commonly built as single-family homes. These sections often include prefabricated panels for walls, floors, and roofs, which reduces the need for cutting and fitting on-site. This approach shortens build time and limits waste compared to traditional single-family homes.

Because the panels are produced in controlled environments, the quality is consistent. Weather delays are also less of a problem since most of the work happens indoors before shipping. Once delivered, the panels can be put together in days rather than months.

Costs vary, but prefabricated builds usually require less labor. A small team can assemble the structure, while specialists handle plumbing, electrical, and finishing. This makes it an option for those who want speed without sacrificing durability.

Key advantages:

- Faster construction timeline

- Less material waste

- Lower labor costs

- Consistent quality from factory production

Modular Homes

Modular homes are built in sections, or modules, inside a factory. Each module includes walls, floors, plumbing, and wiring. These units are then transported and placed on a foundation, where they are joined into a complete house.

Unlike basic prefab homes, manufactured homes arrive more complete. This reduces the amount of finishing work needed on-site. This type of home can normally be assembled in a few weeks once the foundation is ready.

Costs are usually calculated with the area covered, not including land, foundation, or utilities. Builders often save money because manufacturers buy materials in bulk and streamline production.

Why choose modular homes:

- Faster than traditional builds

- Wide range of floor plans and finishes

- Can meet local building codes

- Often more energy-efficient due to tight construction

Alternative and Sustainable Way to Build a House

Some of the most affordable housing options today focus on smaller footprints and the reuse of existing materials. These methods can reduce upfront costs, shorten construction time, and often improve long-term efficiency.

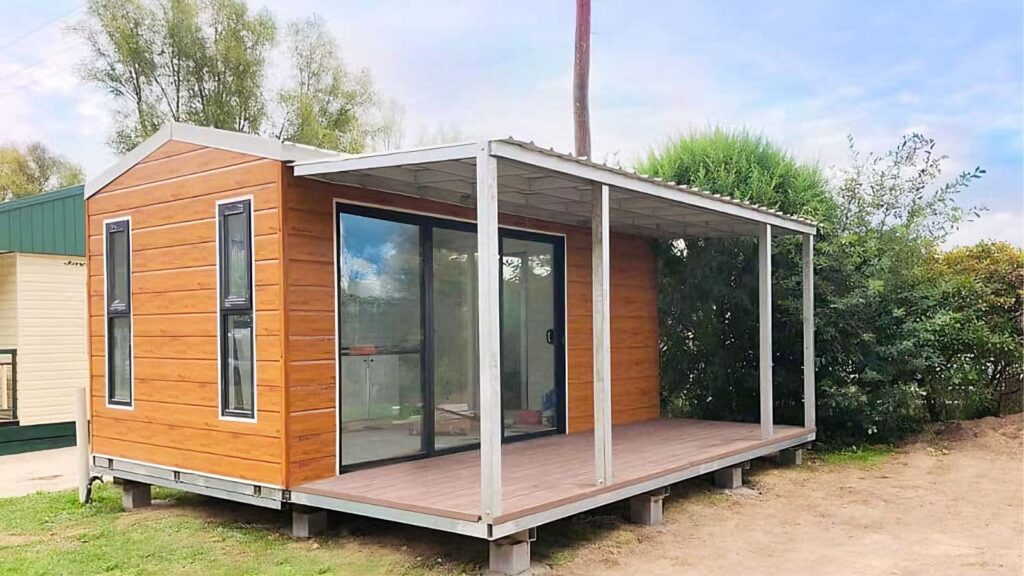

Tiny Homes

Tiny homes are designed to maximize space while minimizing expenses. The costs to build vary greatly, depending on size, design, and whether they are built on wheels or a foundation. If cheaper housing is what you seek, Deepblue Home offers affordable models for as low as $15,000.

Because of their small size, tiny homes require less energy for heating, cooling, and maintenance. Owners often install solar panels, composting toilets, or rainwater collection systems to cut monthly costs.

Keeping layouts simple, using multipurpose furniture, and limiting plumbing to one area of the house save money when building a tiny house. For people comfortable with minimal space, tiny homes provide a practical way to build quickly and avoid large mortgages.

Container Homes

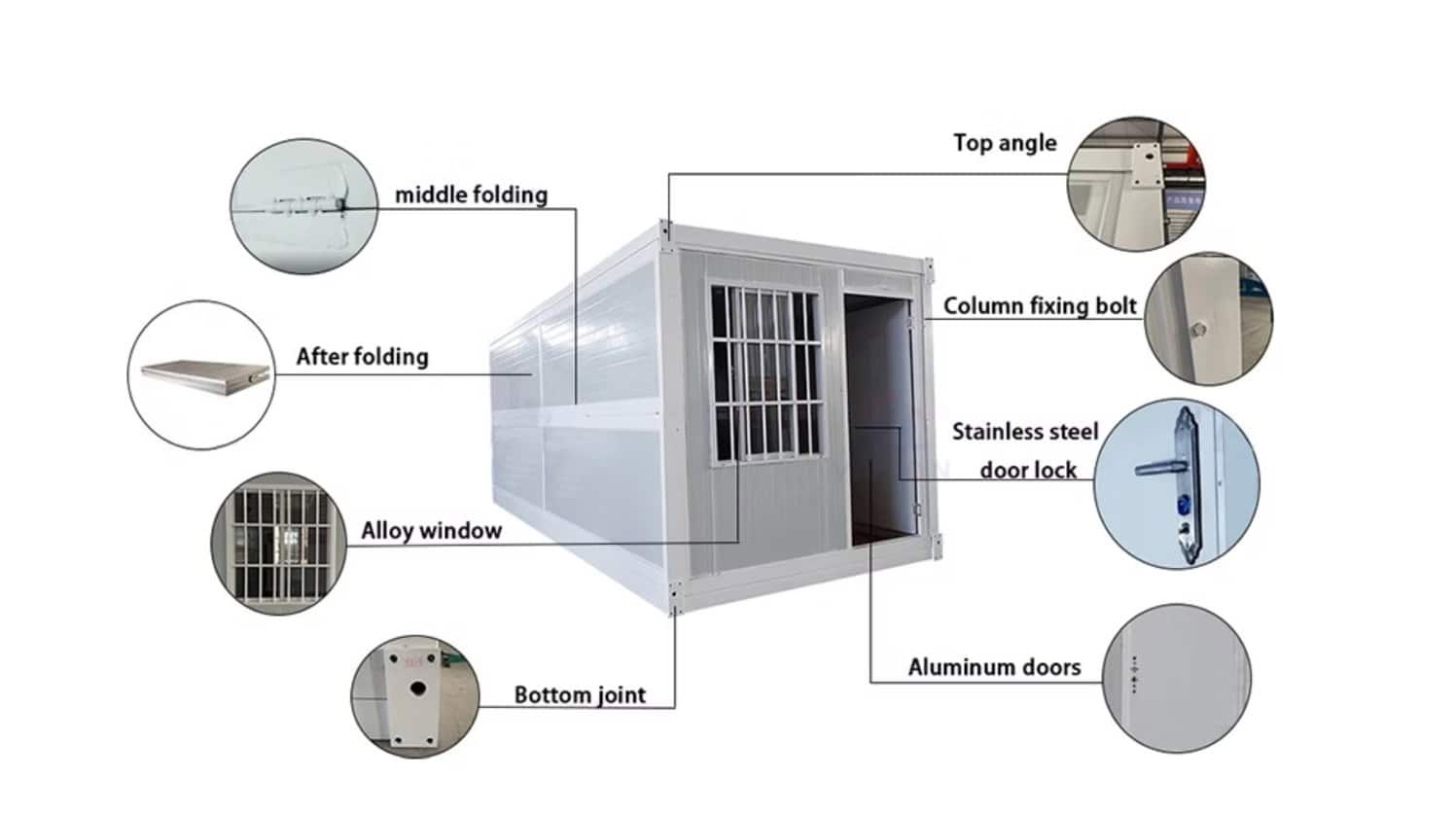

Earlier models of container homes reuse steel shipping containers for the appeal that the basic structure already exists, but they are airtight and not insulated, and also require cutting and welding, which add labor cost. In comparison, Deepblue Home now provides a more advanced foldable container home solution.

These foldable container houses are an innovative and cost-effective solution for various housing needs, from emergency sheds to temporary housing or permanent homes. They are designed to be eco-friendly, energy-efficient, and eliminate the need for extra materials and labor, making them an ideal option for people who need a flexible and affordable housing solution.

In summary, the foldable container house is a practical and versatile housing solution that offers portability, affordability, and flexibility. With high-quality materials, easy assembly, and excellent customer support, it’s a smart choice for anyone looking for a simple, low-cost, and efficient housing solution instead of traditional homes.

Selecting the Cheapest Yet Qualifying Building Materials

Affordable construction often comes down to choosing materials that balance price, durability, and availability. Options such as steel framing, salvaged lumber, and prefabricated concrete panels reduce construction costs while still supporting safe and efficient builds.

Light Gauge Steel

Light-gauge steel framing offers a strong yet affordable alternative to traditional lumber. It resists pests, fire, and warping, which reduces long-term maintenance costs. The material is lightweight, making it easier to transport and install with smaller crews.

Light steel frame construction has several advantages over other construction methods. The frames are comprised of cold-formed light-guage steel, which is non-combustible, meeting the code requirement for specialized structures. It is also strong, flexible and durable, making it easy to build, design and transport and store outdoors because of its resistance to all types of weather. These frames also produce less waste and are highly recyclable owing to the environmentally friendly and cost-effective features of cold-formed steel.

Builders often use steel studs for walls and beams in both residential and commercial projects. Since the pieces are manufactured to consistent dimensions, they fit together with precision, cutting down on wasted material.

Reclaimed Wood and Salvaged Materials

Reclaimed wood and salvaged building materials lower costs while reducing waste. Lumber from old barns, factories, or deconstructed homes can be repurposed for roofing materials, flooring, beams, or wall finishes.

Using salvaged wood helps avoid the high price of new lumber. It also supports sustainability by keeping usable materials out of landfills. However, reclaimed wood may be damaged by rot or pests, rendering it useless in construction.

Concrete Sheets and Panels

Precast concrete sheets and panels provide a fast and cost-effective way to create walls and structural elements. Since they are manufactured in factories, panels arrive ready to install, saving time compared to pouring concrete on-site.

These panels offer strong fire resistance and a long service life. However, it also had some drawbacks: customization is limited, as panels are produced in standard sizes and shapes; its high density increases the total weight of the house; and the surface color and texture can also be rough and unaesthetic without furnishing.

Labor Approaches to Save Money and Time

Careful choices in labor and material sourcing can reduce costs and shorten building schedules. Homeowners often balance personal involvement with professional help and look for ways to secure better prices on essential supplies.

DIY Versus Hiring Professional Contractors

Doing some of the work personally can cut labor expenses, provided that the jobs only require basic skills and tools. However, complex work such as electrical wiring, plumbing, or structural framing usually demands licensed professionals. Mistakes in these areas often lead to safety risks, failed inspections, or expensive repairs.

That’s why Deepblue Home aims to solve two problems in one run. By streamlining everything from materials procurement to construction, it is estimated that a home comes together in four to eight weeks on average. That’s up to eight times faster than the industry average! This not only guarantees reasonable prices from reliable suppliers but also speeds up the home construction process.

Bulk Purchasing and Supplier Negotiation

Buying materials in larger quantities often lowers the unit cost. Contractors and homeowners who plan ahead can order lumber, concrete, or roofing supplies in bulk to secure better pricing. This strategy also reduces delivery fees and avoids delays from running out of materials mid-project.

Negotiating with suppliers can also lead to discounts. Some vendors offer reduced rates for discontinued items, overstock, or builder’s packages. Establishing relationships with local suppliers may provide access to insider deals or flexible payment options.

When combined, bulk purchasing and negotiation help keep material costs predictable. This planning not only saves money but also ensures that construction moves forward without unnecessary interruptions.

Frequently Asked Questions

What is the simplest home design for DIY construction?

A rectangular or square floor plan is the easiest and cheapest to build. Straight walls and a simple roofline reduce labor and material costs. Many DIY builders choose single-story homes because they require less structural work and fewer materials.

How can I minimize costs when building a 2,000 sq ft home?

Using cost-effective materials like concrete blocks, prefabricated panels, or engineered wood can lower expenses. Keeping the layout open and avoiding unnecessary corners or complex roof designs also helps. Doing some of the finishing work, such as painting or flooring, can cut labor costs.

What strategies are available for constructing a house under $20,000?

Small-scale builds such as tiny homes, cabins, or container houses often fall within this budget. Using recycled or salvaged materials can reduce costs further. Building on land with minimal site preparation needs also helps keep expenses low.

Where globally can I build a home most affordably?

Countries in parts of Southeast Asia, Central America, and Eastern Europe often have lower labor and material costs. Rural areas usually offer cheaper land compared to urban centers. However, availability of materials, building codes, and infrastructure should always be considered when choosing a location.