Imagine this: you finally purchased a plot of land, ready to become a homeowner. After searching through plans for wooden framed single-family house online like everyone else, you came across the concept of steel frame house, but is unsure about if deviating from the traditional practice of wood frame would be bring unforseen problems. You need a solution to answer your questions, and that is why today at Deepbluehome , we will share the pros and cons about both types of frames and help you understand these differences, so as to make well-informed decisions for both the immediate needs and the future performance of your dream house.

Application:

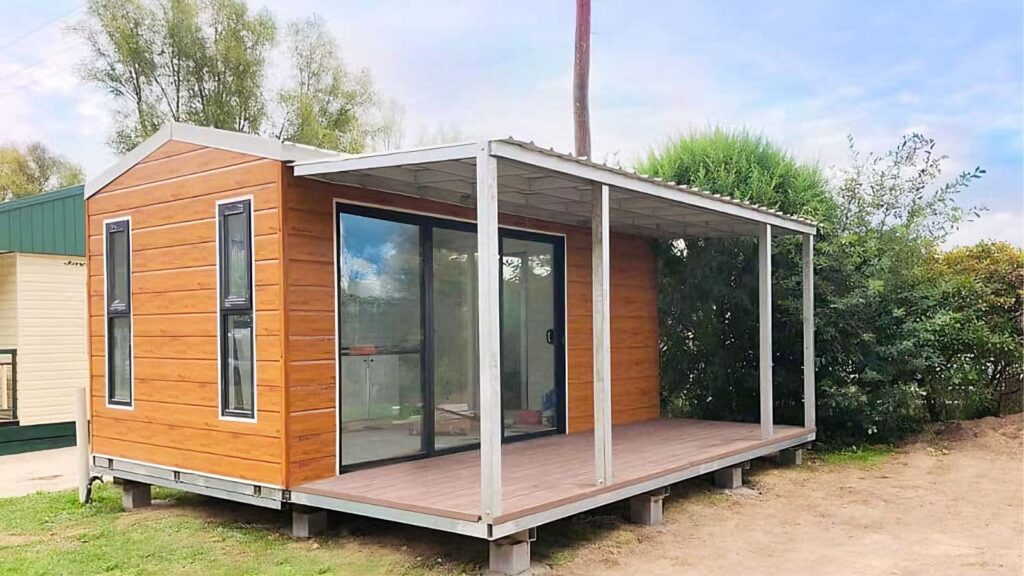

Our prefabricated light steel frames serve as the essential main building structure for high-end constructions such as Luxury Homes, Townhouses, Duplexes, Guest Houses, Resorts, and Cabins. In-house design and manufacturing ensure unmatched quality and reliability.

Core Differences Between Steel Framing and Wood Framing

Steel framing and wood framing differ in how they handle weight, resist environmental forces, and how they are produced and installed. Their performance depends on the material properties, manufacturing processes, and construction techniques used.

Structural Strength and Durability

Steel framing, especially when made from galvanized steel, resists rust, warping, shrinking, and insect damage. It maintains structural integrity against natural disasters and general wear and tear over long period of time.

Wood framing is lighter, provides better insulation and easier to work with but is more vulnerable to moisture, rot, and termites. Over time, wood can expand, contract, or twist with changes in humidity.

In steel vs wood framing, steel generally offers a longer lifespan in harsh environments without too much hustle. In comparison, if one wish to maintain the condition of wood frame for decades, properly treatment and maintainance is needed, even in moderate climates.

| Feature | Steel Framing | Wood Framing |

|---|---|---|

| Pest Resistance | High | Low |

| Moisture Resistance | High | Moderate to Low |

| Load Capacity | High | Moderate |

Material Composition and Manufacturing

Steel framing uses cold-formed steel studs or structural steel members. These are often coated with zinc to create galvanized steel, which helps prevent corrosion. The manufacturing process produces uniform components with consistent dimensions.

Wood framing uses dimensional lumber such as 2×4 or 2×6 boards, as well as engineered wood products like laminated veneer lumber. These materials are cut from trees and may vary slightly in shape and density.

Steel production requires more industrial processing, but it allows for recycling without losing strength. Wood is a renewable resource, but its quality depends on the species, grade, and treatment used.

Installation and Construction Methods

Steel framing requires cutting steel studs to length and fastening them with screws or specialized tools. Workers often use pre-punched holes for running electrical wiring and plumbing. The process demands precision and sometimes more training.

Wood framing is generally faster for crews familiar with traditional carpentry. Lumber can be cut with standard saws and joined with nails or screws.

Steel framing is common in commercial construction projects and some residential builds where strength and fire resistance are priorities. Wood framing remains dominant in single-family homes due to lower material costs and simpler installation methods.

Cost Considerations and Long-Term Value

Steel framing and wood framing differs greatly in terms of cost considerations and long-term value. Local labor rates, climate, and building size also affect the overall value of each option.

Initial Material and Labor Costs

Steel framing generally has a higher material cost, sometimes costing two to three times more than wood upfront. However, this can be offset by its reduced expenses over time due to its durability and low maintenance needs. If the timespan is stretched into decades, it is estimated that the overall expense for steel framing will be 70% less than that of wood framing.

Labor costs also differ. Steel framing often requires specialized tools and training, and fewer contractors can handle it, but that is not the case for Deepbluehome’s products as we offer quality on-site assembly support, ensuring your project is completed efficiently and on time.

Maintenance and Repair Expenses

Steel framing resists rot, termites, and warping. It is non-combustible, and can withstand severe weather better than wood. This means fewer repairs and less frequent maintenance.

Wood framing needs more upkeep over its lifetime. Issues like moisture damage, pest infestations, and fire risk can require repairs or replacements.

Over decades, these costs add up. A building with steel framing may need only minor upkeep, while a wood-framed building could require multiple repairs.

In humid or pest-prone regions, steel’s resistance to biological damage can result in significant long-term savings. In dry, mild climates, wood’s maintenance needs may be less of a concern.

Resale Value and Insurance Factors

Insurance companies often view steel framing as lower risk for fire and pest damage. This can lead to lower premiums compared to wood framing.

Wood framing’s higher fire risk and susceptibility to damage may increase insurance costs. However, in some areas where wood is the standard, the difference may be small.

Resale value can also be influenced by framing choice. Buyers in disaster-prone areas may value steel’s durability, while those in traditional markets may prefer wood for its familiarity and ease of renovation.

Local building codes, buyer preferences, and climate risks all play a role in how framing material impacts both resale and insurance costs.

Choosing the Right Framing for Your Project

The choice between steel and wood framing often depends on the building’s size, intended use, and performance needs. Factors like load capacity, design complexity, local weather risks, and construction speed can influence which material is the better fit.

Steel framing offers strong load-bearing capacity, making it suitable for multi-story buildings, large spans, or open floor plans. Steel studs can support wide layouts without extra interior walls, which benefits modern homes with open concepts.

Wood framing works well for smaller residential projects where traditional layouts are preferred. It is easier to cut and modify on-site, which can speed up custom adjustments.

For complex architectural designs, steel allows for precise prefabrication, which is also another specialty of Deepbluehome. Components can be made off-site to exact measurements, reducing waste and rework. In contrast, wood may require more on-site adjustments, especially for irregular shapes or large openings.

| Feature | Steel Framing | Wood Framing |

|---|---|---|

| Span Capability | Long, open spans | Shorter spans |

| On-Site Modifications | Limited | Easy |

| Prefabrication | Highly suitable | Less common |

Our experienced team works with you to create a smart, practical design. We then source high-quality materials and manufacture every component with precision in our own factory. Once ready, your complete home structure is carefully packed and shipped directly to your nearest port — a smooth, coordinated process from our floor to your shore.

This streamlined approach ensures quality control at every step, saves you time, and provides a clear, reliable timeline for your project.

Our experienced team works with you to create a smart, practical design. We then source high-quality materials and manufacture every component with precision in our own factory. Once ready, your complete home structure is carefully packed and shipped directly to your nearest port — a smooth, coordinated process from our floor to your shore.

This streamlined approach ensures quality control at every step, saves you time, and provides a clear, reliable timeline for your project.