According to the “Australia Real Estate Market Outlook 2026-2030” report released by Propertybuyer, by 2030, Australia is expected to face a housing construction gap of up to 500,000 units. This severe imbalance between supply and demand will lead to a continuous rise in house prices and may cause further significant increases in prices in major cities. This will further accelerate the application of Light Gauge Steel(LGS) buildings in both residential and commercial sectors.Not only in Australia, In the ever-evolving world of construction, light gauge steel homes are emerging as a dynamic alternative to traditional building methods.

The advantages of LGS are high degree of industrialization, rapid construction, low carbon emissions and environmental friendliness. In the future, they will become more intelligent and personalized.

- High degree of industrialization

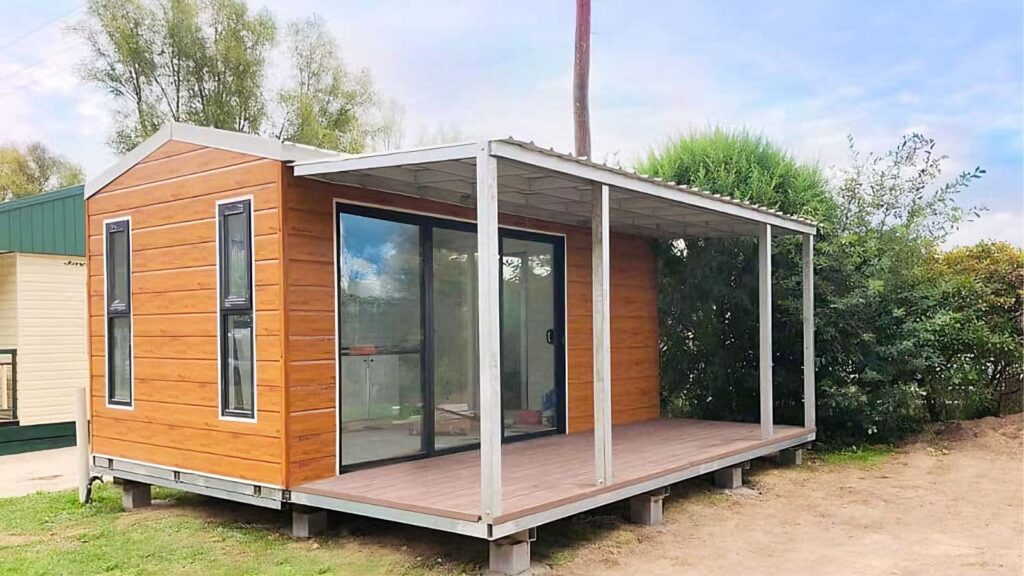

Adopting prefabricated production, the structure is simple and the installation efficiency is high.

Environmental protection and energy conservation: The light steel villa has excellent heat insulation performance and a low formaldehyde content, meeting the demands of modern green and healthy residential buildings.

Stable structure: Using cold-rolled light steel keels produced with hot-dip galvanized aluminum steel strips, it has a good anti-corrosion barrier function.

- Advantages of adapt to extreme climates

Fire resistance and pest resistance: In areas with high risk of forest fires, the non-combustibility of steel is its core strength. At the same time, it is completely immune to termite damage。

- Environmental protection and energy efficiency

Low-carbon and environmentally-friendly: The steel frame combined with new insulation materials can achieve twice the insulation performance of traditional brick walls.The 100% recyclable property of steel aligns can achieve with promoting green buildings.

4.Solving the housing shortage and labor costs

Ultra-fast delivery: Light steel villas can usually be delivered within 3 to 6 months, with the construction period being approximately half that of traditional methods.

cost reduction: The overall labor cost is significantly reduced by shortening the construction period and reducing on-site waste (reducing waste by approximately 25%).

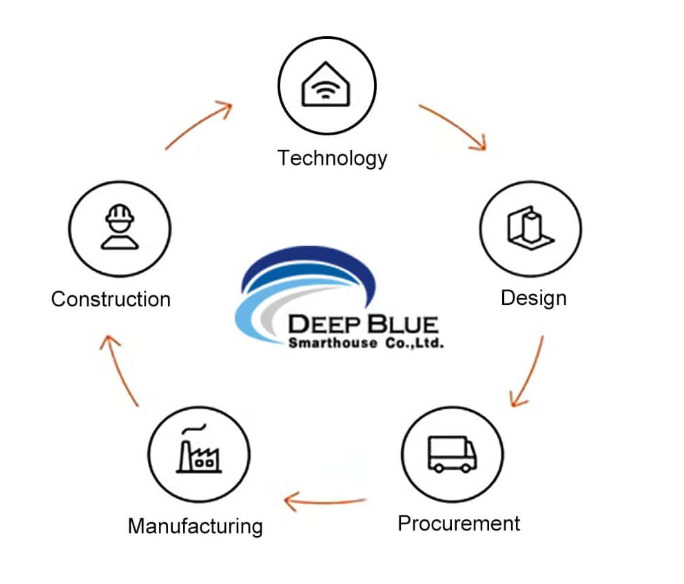

Deepblue Smarthouse, established in 2009, is a pioneer in offering modern methods of construction (MMC) technology. We provide end-to-end building solutions that are not only innovative but also sustainable, making a significant contribution to eco-friendly housing. Our mission is to build smarthouses globally, with an aim to eradicate homelessness.

Professional in Smarthouse projects

We are fully integrated, providing end-to-end building services as a single partner, with CNC technology systems connecting everything together.With 78 patents, 15years experience, over 1million sgm per year,supplied over 10000 homes, which make us more and more professioanl.

Better Price

Long-term working system and flexible supply chain contribute to competitive price.

Better Design

We have professional design team to meet different design options.

Better Quality

Put quality as our top priority, from technical specification to construction.

Overall, Light Gauge Steel(LGS), with its characteristics of speed, environmental friendliness, and customizability, are expected to occupy a more significant position in the future housing market and continuously evolve towards efficiency and high cost-effectiveness.

It is believed that in the near future, architecture will not only be a living space but also a means of shaping lifestyle, being solid, simple, and beautiful, making it an integral part of our daily lives.