Ever wondered what goes into producing high-quality prefabricated homes and advanced injection molding equipment? In our latest video, we invite you to step inside the world of Deepblue Manufacturing. This exclusive glimpse into our daily operations shows how we combine state-of-the-art automation, skilled craftsmanship, and rigorous quality control to deliver durable, efficient, and cost-effective solutions for clients worldwide. Whether you’re a real estate developer, builder, or curious viewer, this is your chance to see how innovation meets precision in every aspect of our production.

1. Raw Materials: The First Step to Quality

At Deepblue Manufacturing, quality begins with sourcing the best raw materials. Our daily routine starts with the careful inspection and quality assessment of each incoming shipment. Ensuring the highest quality from the very start is essential in producing durable, lightweight steel frame structures and high-performance injection molding machines. The video showcases our strict quality assurance measures to meet both international standards and client expectations.

2. Precision in Every Detail: Automated and Skilled Craftsmanship

Automation and skilled craftsmanship are the foundation of our production process. Using advanced machinery and a dedicated team of technicians, we achieve precision in every phase—from machining components to assembling complex systems. The video captures these synchronized efforts in real-time, where technology and teamwork transform raw materials into finely engineered products. This blend of automation and skilled labor not only accelerates production but also enhances accuracy, making our prefabricated homes and equipment highly reliable.

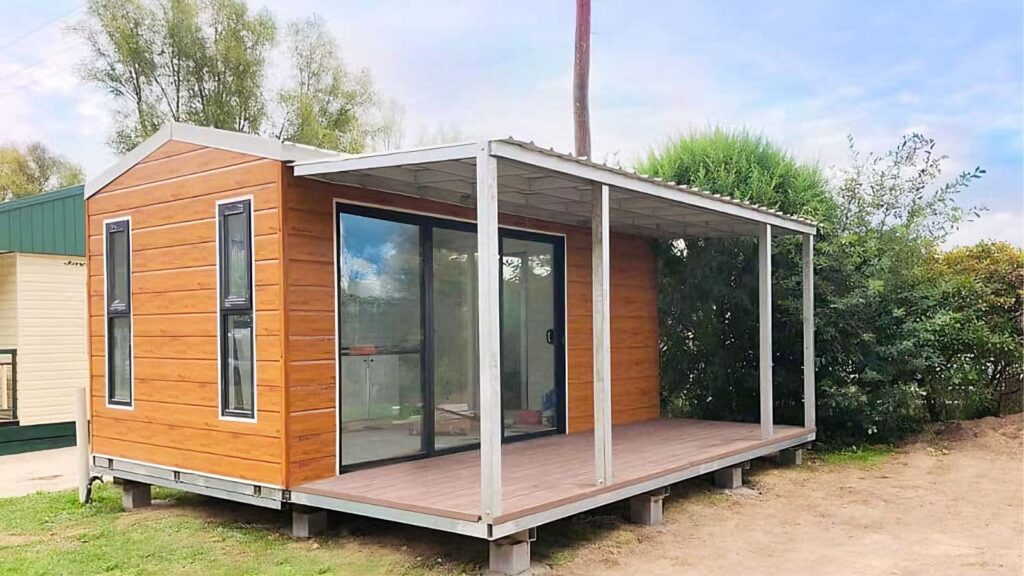

3. Production of Steel Frame Components for Prefabricated Homes

Deepblue Manufacturing is known for its light steel frame system for housing, offering clients durable and cost-effective building solutions. The video reveals the complete production process for these components, showcasing our commitment to quality at each step. From steel cutting and shaping to the final assembly, every phase is monitored to ensure compliance with international standards. This meticulous approach is why Deepblue’s light steel frames are both strong and lightweight, able to withstand harsh weather conditions while offering quick on-site assembly.

4. Advanced Injection Molding Equipment Production

In addition to prefabricated housing, Deepblue also produces high-efficiency injection molding machines. Our daily production routine involves precision engineering and consistent testing, ensuring our equipment meets the specific needs of clients in various industries, from automotive to consumer goods. By optimizing machine designs and focusing on energy efficiency, we deliver equipment that is economical and environmentally friendly, enabling clients to produce high-quality products with lower operational costs.

5. Committed to International Standards and Customer Satisfaction

A significant part of our daily operations is meeting international standards. Deepblue Manufacturing follows strict industry certifications such as ICC-ES, EN, and AS/NZS, ensuring that each product we produce can be confidently used in global markets. This dedication to quality and safety reflects in every aspect of our production process. Our attention to detail, consistency, and ability to customize according to client specifications make us a trusted partner for projects worldwide.

6. Building a Sustainable Future

Sustainability is at the heart of Deepblue Manufacturing. By using efficient materials and reducing waste throughout the production process, we strive to minimize our environmental footprint. Our prefabricated homes are designed with energy efficiency in mind, helping clients reduce operational costs while promoting greener living spaces. This commitment to sustainability extends to our injection molding equipment, which is engineered for optimal energy usage and longevity.

Conclusion

Watching our daily production video is an eye-opening experience that reveals the dedication, precision, and expertise that go into each Deepblue product. Whether it’s a high-strength light steel frame for a new home or a customized injection molding machine, you’ll see how our team’s hard work and cutting-edge technology create solutions that are built to last. Dive into the video and experience the organized bustle of Deepblue Manufacturing – where quality, efficiency, and innovation come together to shape the future of construction and manufacturing.

Key Takeaways:

-

Insight into Deepblue Manufacturing’s commitment to quality control and international standards

-

The role of automation and skilled labor in producing durable prefabricated homes

-

An overview of our injection molding equipment production, designed for efficiency and sustainability

-

Our dedication to sustainability, reducing waste, and promoting energy-efficient products

Explore Our Video

Watch our video to experience a day in the life of Deepblue Manufacturing and see firsthand how we bring high-quality, innovative products to life. For more insights, follow us on [our YouTube channel](insert link) and stay updated on our latest projects and technological advancements!