In recent years, light steel frame construction has emerged as a powerful solution in the modern housing industry. As demand grows for eco-friendly, durable, and affordable housing, developers and builders are turning to this innovative construction method. Here, we explore the key benefits of light steel frame construction, compare it with traditional timber framing, highlight the advantages of a China-based supply chain, and introduce Deepblue Smarthouse—a leader in light steel frame prefab housing with rich international expertise.

Timber Frame vs. Light Steel Frame: A Quick Comparison

Before diving into the specific benefits of light steel frame construction, let’s take a look at how it compares to the traditional timber frame method across several key areas:

|

Feature |

Timber Frame |

Light Steel Frame |

|

Durability |

Prone to warping, cracking, and rotting over time, particularly in humid climates. |

Highly durable, resistant to warping, cracking, and immune to rot and pests. |

|

Strength & Weather Resistance |

Strong but can be compromised in extreme weather (e.g., heavy snowfall, hurricanes). |

Extremely strong, capable of withstanding earthquakes, hurricanes, and extreme weather. |

|

Fire Resistance |

Combustible; requires chemical treatments for enhanced fire resistance. |

Non-combustible and naturally fire-resistant, reducing fire risk. |

|

Sustainability |

Renewable but requires large quantities of lumber. |

Recyclable and highly sustainable with minimal environmental impact. |

|

Construction Speed |

Fast construction but requires significant on-site work. |

Prefabricated for faster, streamlined construction on-site. |

|

Maintenance |

Requires frequent maintenance for pest and moisture control. |

Minimal maintenance due to resistance to pests, moisture, and corrosion. |

|

Cost-Effectiveness |

Often requires chemical treatments and maintenance costs. |

Cost-effective over time with lower maintenance and repair costs. |

Key Benefits of Light Steel Frame Construction

-

Strength and Durability

Light steel frames are incredibly strong yet lightweight, making them ideal for long-lasting construction. Unlike traditional timber frames, steel resists common issues like warping, shrinking, and cracking, especially in humid or wet climates. Furthermore, steel framing can withstand extreme weather conditions, including hurricanes, earthquakes, and heavy snowfall, offering peace of mind to homeowners. This durability translates to fewer repairs and lower maintenance costs over time.

-

Eco-Friendly and Sustainable

Sustainability is a priority in today’s construction industry, and light steel frame homes are environmentally friendly in several ways:

-

Recyclable Material: Steel is one of the most recycled materials globally, and using it reduces the demand for new raw materials, helping conserve forests and natural resources compared to timber frames.

-

Reduced Waste: Prefabricated light steel frames are manufactured off-site with precision, minimizing on-site waste and reducing the carbon footprint.

-

Energy Efficiency: Light steel frames support better insulation options, enhancing energy efficiency within homes. Improved insulation helps regulate indoor temperatures, leading to reduced heating and cooling costs for homeowners.

-

-

Speed of Construction

One of the primary advantages of light steel frame construction is the speed it brings to the building process. The frames are prefabricated in factories, which reduces on-site labor and construction time. This method also allows for simultaneous activities, like site preparation and frame manufacturing, shortening the overall project timeline. Timber framing, though quick, requires more extensive on-site work and can be impacted by weather delays. For developers, this faster construction speed with steel means reduced labor costs and quicker project completion.

-

Cost-Effective Solution

While timber can sometimes offer a lower initial cost, light steel frame construction can be more cost-effective in the long run due to its durability and low maintenance. Steel frames do not require frequent treatment for pests, mold, or fire resistance, unlike timber, which often needs chemical treatments. Over the lifespan of a home, savings on repair and maintenance make steel a more economical choice. Additionally, the lightweight nature of steel reduces transportation costs and minimizes the need for heavy equipment on-site.

-

China-Based Supply Chain Advantage

Choosing a China-based supplier for light steel frame construction brings unique advantages:

-

Significant Cost Savings: By leveraging China’s extensive building materials supply chain, costs can be reduced by up to 50% compared to other markets. This cost-efficiency makes light steel frames even more competitive than timber, allowing developers to maximize their budget.

-

Quick and Efficient Delivery: With established infrastructure and mass production capabilities, Chinese suppliers can expedite delivery times, enabling projects to start and finish sooner. This efficiency is critical for developers looking to meet tight project timelines and handle larger-scale developments.

-

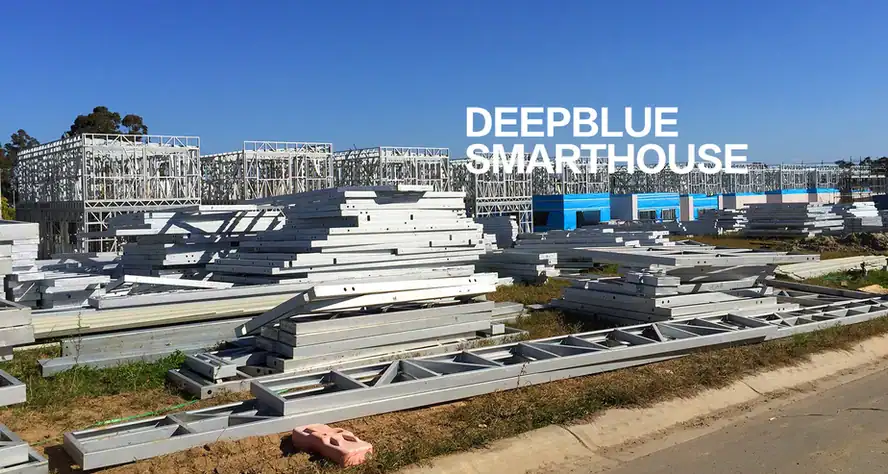

Mass Production Capabilities: China-based suppliers are equipped for high-volume production, ensuring consistent quality and ample supply for even the largest projects. This reliability reduces the risk of delays and supports long-term project planning with dependable output.

-

-

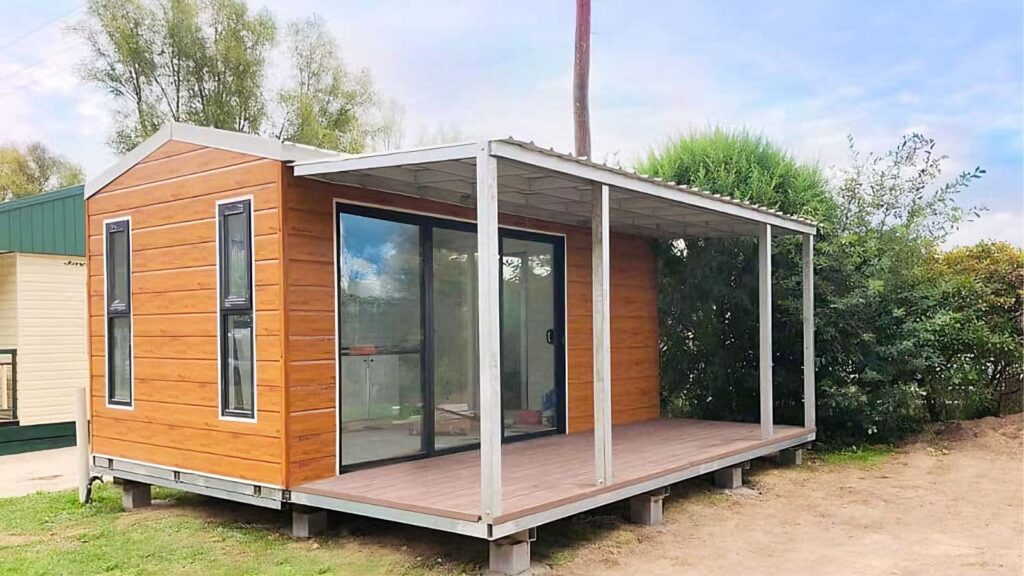

Working with Deepblue Smarthouse: The Leading Light Steel Frame Supplier in China

Deepblue Smarthouse has established itself as one of China’s top providers of light steel frame prefab housing solutions. With over 14 years of experience, Deepblue Smarthouse is the go-to partner for developers worldwide. Here’s why:

-

International Project Expertise: Deepblue has delivered projects in over 60 countries, working with a wide range of building requirements and adapting to diverse construction standards.

-

In-House Design Team: The skilled in-house design team provides tailored solutions, ensuring each project meets local standards and aesthetic preferences.

-

World-Class Production Line: Equipped with advanced manufacturing technology, Deepblue Smarthouse offers high-quality, precise light steel frames capable of mass production.

-

Global Construction Standards: Deepblue Smarthouse’s products meet international standards such as AS/NZS (Australia and New Zealand), ICC-ES (USA), BS (UK), CE (Europe), and EN standards, ensuring compliance and safety across all markets.

-

-

By partnering with Deepblue Smarthouse, developers can access a trusted and proven supplier with the expertise, infrastructure, and resources to support efficient, high-quality housing projects worldwide.

-

Design Flexibility

Modern housing trends emphasize open floor plans and spacious, adaptable spaces. Light steel frames offer superior design flexibility, supporting larger spans and allowing for more open spaces without bulky support structures. While timber can limit design options due to its structural needs, steel framing can accommodate diverse architectural designs, making it easier to cater to different client preferences and enhancing the visual appeal of residential properties.

-

Fire Resistance and Safety

Safety is paramount in housing construction, and light steel frames excel in this area. Steel is non-combustible and resistant to fire, whereas timber requires chemical treatments to reduce fire risk. In regions prone to wildfires, the fire-resistant properties of steel offer added protection, making it a safer choice for both developers and homeowners.

-

Pest and Mold Resistance

Timber framing is susceptible to pests like termites and often requires treatments to deter infestations, adding to maintenance costs. Additionally, timber is vulnerable to moisture damage, leading to mold and mildew issues. Light steel frames, however, are immune to these problems, providing a longer-lasting and healthier environment for occupants without the need for frequent chemical treatments.

-

Precision and Quality Control

With light steel frame construction, each component is manufactured in a controlled factory environment, ensuring consistency and quality. This precision reduces errors that can occur with timber frames constructed on-site. As a result, builders can rely on precise measurements and high-quality materials with steel, enhancing structural integrity and home longevity.

Conclusion: Light Steel Frame Construction is the Future of Modern Housing

The numerous benefits of light steel frame construction make it an attractive solution for today’s housing needs. Compared to timber framing, light steel frames offer increased strength, durability, and resistance to natural elements, making them a wise choice for developers aiming for sustainable, long-lasting, and cost-effective housing solutions. By working with Deepblue Smarthouse—a leading supplier with rich international project experience, a world-class production line, and expertise in global construction standards—developers gain a trusted partner that understands the importance of quality, efficiency, and compliance.

If you’re a developer or builder exploring innovative construction methods, consider the advantages of light steel framing with Deepblue Smarthouse. It’s a smart investment that adds value to properties and provides lasting benefits for homeowners and the environment alike.

https://www.deepbluehome.com/light-steel-framing