Steel is the most common building material in the modern world, and often praised for its strength and durability. But many people wonder if this material is truly kind to our planet, and that is exactly what this article at Deepblue Home will answer.

We will explore the environmental footprint of light steel frame (LSF) production and use, and demonstrate its high recyclability, efficient construction process, and low carbon footprint, as well as the energy-intensive processes behind its creation.

The Environmental Impact of Light Steel Construction

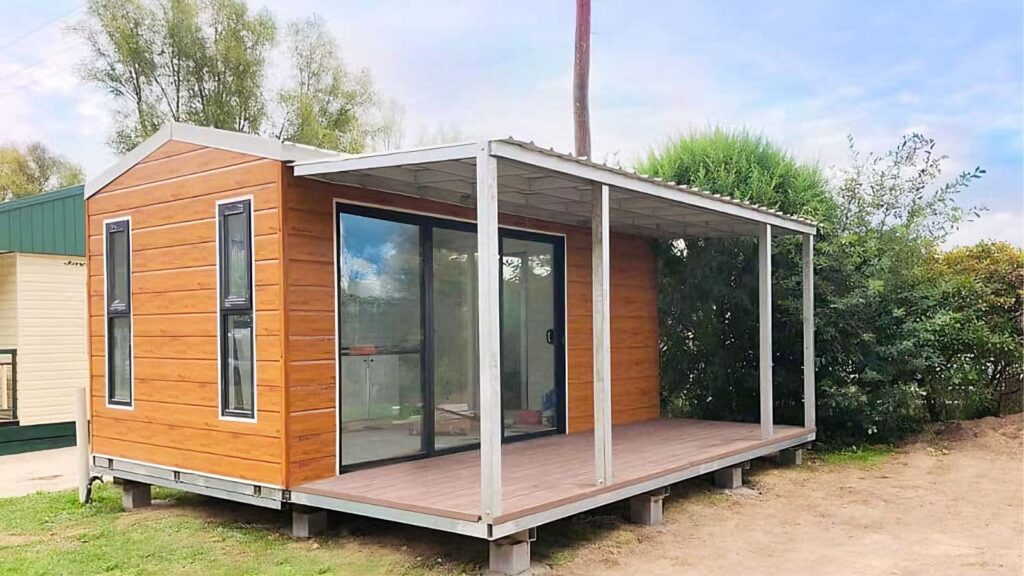

Light steel construction offers specific environmental advantages over traditional methods. Its production and application processes significantly reduce waste and energy consumption.

Prevent Waste and Pollution

Light steel construction generates less waste than conventional building techniques. As the majority of the waste and pollution created by conventional construction comes from both the process and the materials used.

Off-site fabrication ensures precise manufacturing; every part is accounted for, and nothing goes to waste. This not only eliminates most on-site cutting and shaping but also minimizes material excess. The construction crews will no longer leave behind empty cement bags, broken bricks, trimmed-off wastes from wood or metal, and piles of sawdust that litter everywhere. Neither will the homeowner pay extra for the removal of the trash and waste.

What many won’t notice is that this method also reduces the need for heavy-duty construction vehicles, as light steel frames come with pre-punched holes. These pre-engineered holes eliminate the need for drilling, ensuring a fast, accurate, and secure fit with standard fasteners. The lightweight of the frame suits smaller lifting riggings and also enables manual assembly to a certain degree. The residents around the work site won’t file noise complaints to authority, and builders could be spared from unpleasant diesel fumes. It is a win-win situation!

What’s more important is these features do not just apply to single-family homes; they also work in townhouses, prefab villas, integrated hotel units, etc. In fact, the bigger the projects, the more evident the benefits of light steel frames.

Lower Energy Consumption and Reduce Emissions

The production methods of cold-formed steel and hot-rolled steel are vastly different, and so are their energy consumptions. Here is a detailed comparison:

- Hot-rolled steel is manufactured by heating steel above its recrystallization temperature and then rolling it into shape. This process typically consumes more energy because high temperatures are required to soften the steel for deformation.

- Cold-formed steel is processed at or near room temperature, skipping the need for extreme heating. This results in lower direct energy consumption in the rolling process compared to hot-rolled steel.

In the past, steel was regarded as an inefficient option for building because of its higher thermal conductivity. Many worry that this would render indoor heating ineffective.

However, these issues have been addressed in light steel construction through improved designs:

- Thermal breaks: Insulation layers or thermal barriers are added around steel components to interrupt the path of heat transfer.

- Composite wall systems: Instead of constructing walls purely out of steel, modern designs incorporate multi-layered wall systems combining steel framing, advanced insulative materials, and energy-efficient cladding, further enhancing thermal efficiency.

Such features improve the energy efficiency of light steel frames, which leads to less heating required and contributes to the reduction in CO2 emissions.

Recyclable Light Steel Frames

Light steel frames offer exceptional environmental benefits through their high recyclability and efficient use of materials. These frames support sustainable construction practices by minimizing waste and energy consumption.

Endless Recycling Without Quality Loss

Steel maintains its structural integrity through infinite rounds of recycling. These processes involve melting steel scrap and reforming it into new steel products. Each recycled batch retains the strength and durability of virgin steel. North American structural steel contains over 90% recycled content.

Global recycling meets approximately 26% of steel demand. Some countries achieve recycling rates exceeding 85%. Light steel frames from demolished buildings become new construction materials. This closed-loop system reduces the need for steel supply and iron ore mining, which conserves natural resources and decreases landscape disruption.

Steel mills efficiently process scrap into high-quality frames, and manufacturers produce new light steel components using recycled material. Endless recyclability ensures steel remains a sustainable building option.

Reducing Landfill Waste

Light steel frame construction significantly lowers landfill contributions. As previously stated, all the components will end up in the frame of the buildings, and there will be no extra material packaging waste. By employing such a method, material waste is reduced by approximately 90%.

Even if these steel frames are somehow put into waste disposal, their magnetic properties allow easy separation from mixed debris. Recycling diverts massive volumes of construction waste from landfills.

Each ton of recycled steel saves 2,500 pounds of iron ore. It also conserves 1,400 pounds of coal and 120 pounds of limestone. Using light gauge steel helps landfills reduce bulk waste with steel recovery. Meanwhile, construction sites generate less pollution through efficient steel use.

Advancements in Green Steel

Green steel production utilizes innovative technologies to drastically reduce carbon emissions from traditional steelmaking. These advancements focus on replacing fossil fuels with clean energy sources and improving overall process efficiency.

Low-Carbon Production Methods

Green steel relies on two primary low-carbon production methods: hydrogen-based direct reduced iron and electric arc furnaces (EAF). Hydrogen-based direct reduced iron replaces coal with hydrogen as the reducing agent, producing only water vapor instead of carbon dioxide. Electric arc furnaces work as substitutes for traditional blast furnaces, melting recycled scrap steel using electricity, and significantly lowering emissions compared to virgin iron ore processing.

Both methods depend on renewable energy sources to achieve their full environmental potential. The steel industry reports a 37% reduction in greenhouse gas emissions since 1990 due to these efficiency improvements and cleaner technologies. Water management and recycling practices further enhance steel sustainability by reducing pollutants and consumption.

Major companies like SSAB, ArcelorMittal, and Thyssenkrupp invest heavily in scaling these technologies for full commercial deployment. These innovations face challenges in scaling clean hydrogen production and accelerating the transition from coal-based blast furnaces. The industry targets large-scale green steel production by 2035, contingent on overcoming hydrogen availability and renewable energy integration hurdles.

Overcoming Barriers and The Path to Net-Zero

While the potential of green steel is immense, its widespread decarbonization attempt faces hurdles. The high cost and current technological immaturity of processes like hydrogen-based steelmaking make them expensive and not yet scalable for mass production. Furthermore, the limited availability of green hydrogen and the need for a more robust renewable energy infrastructure are significant challenges. Sourcing low-carbon raw materials adds logistical complexity, and regulatory delays can slow the rollout of new technologies.

However, the path towards carbon neutrality is clear. The transition to net-zero steel hinges on key strategies: scaling up hydrogen-based reduction to replace coal, powering production entirely with renewable energy like solar and wind, and further expanding recycling rates to utilize existing resources. Supportive policies, such as carbon pricing and green certifications, are also crucial to drive market demand. Major companies are investing heavily, with the goal of large-scale commercial green steel production by 2035. Overcoming the current barriers in hydrogen availability and renewable energy integration is the critical next step for the industry.

Steel in Sustainable Light Steel Frame Housing

Steel framing provides significant environmental advantages in modern construction, particularly through its durability and integration with renewable energy systems.

Durability, Longevity, and Energy Efficiency

Steel structures resist corrosion, pests, moisture, and natural disasters, ensuring an extended service life that reduces resource consumption and waste generation over time. The material’s longevity means fewer replacements and associated environmental impacts. Furthermore, steel framing supports the installation of thicker insulation, improving thermal performance and decreasing energy use for heating and cooling.

Applications in Renewable Energy

Steel’s strength enables reliable support for heavy renewable energy equipment, such as solar panels and wind turbines. This integration facilitates the transition to green energy by embedding renewable systems directly into building infrastructure. The material’s durability also ensures long-term stability for these installations, maximizing their efficiency and lifespan.

Conclusion

Light steel framing presents a compelling answer to the construction industry’s search for sustainable materials. Its high recyclability, efficient off-site production, and incredible durability undeniably reduce its environmental footprint across its entire lifecycle and contribute to the generally lower energy intensity around the globe.

While the energy-intensive nature of its creation remains a challenge, the industry’s rapid advancement in green steel production paves the way for a truly net-zero future. The framework for sustainable building now exists; and it’s only a matter of adoption and innovation.

Ready to build your vision with the strength and sustainability of light steel framing? Find out more at Deepblue Home!

Frequently Asked Questions

Is light steel frame construction more expensive than traditional wood framing?

Initially, light steel frame (LSF) can have a higher material cost. However, this is often offset by savings from faster construction times, reduced labor costs due to prefabrication, and lower long-term expenses thanks to its durability, minimal maintenance needs, and superior energy efficiency. The total lifecycle cost can be very competitive.

Can light steel frames be used for all types of homes, including custom designs?

Absolutely. One of the key strengths of LSF is its design flexibility. The precision of computer-aided design (CAD) and off-site fabrication allows for the creation of complex and highly customized architectural designs, from modern minimalist homes to more traditional styles, with great accuracy.

What is being done to improve the sustainability of steel even further?

Beyond the production methods mentioned, research is focused on improving the efficiency of recycling processes, developing new coatings that are more environmentally friendly, and creating even lighter and stronger steel alloys that use less material without compromising strength, further reducing the embodied carbon of each frame.