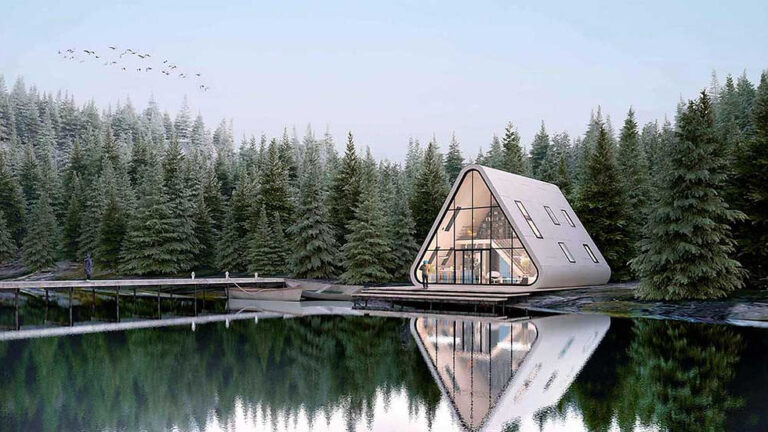

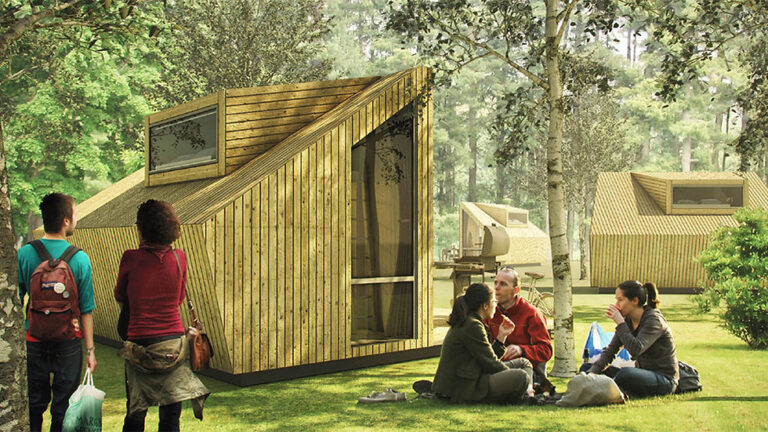

Horn Cabin offers a unique tree-top experience, situated 10 meters above the ground in a forested area. With its elevated position, guests can take in stunning views of the surrounding river and region from the cabin’s window-lined facade. Inside, the cabin combines design, comfort and relaxation with amenities such as a high-quality bed, bathroom, glass-enclosed shower, heated floor, sound system, and fully equipped kitchen. The cabin’s full wall of windows allows for plenty of natural light to enter and enhances the overall tree-top experience.

The process of constructing a light steel cabin typically involves the following steps:

Design and Planning: The first step is to create a design that meets the requirements of the client, including the layout, size, and style of the cabin.

Preparation of the Foundation: The foundation must be level and stable to ensure the stability of the cabin. This may involve excavation and concrete pouring.

Assembly of the Steel Frame: The light steel frame is constructed on site, including the floor, walls, roof, and any other structural elements.

Installation of Services: This includes the installation of electrical, plumbing, heating, and ventilation systems.

Insulation and Wall Cladding: Insulation is added to the walls and roof to improve energy efficiency and comfort. The exterior walls are then clad with the chosen wall panels.

Finishing Works: This includes the installation of windows, doors, flooring, and any other finishes.

Final Inspection: A final inspection is carried out to ensure that the cabin meets all relevant building codes and standards.

Occupancy: Upon completion, the cabin is ready for occupancy.

Note: The exact process may vary depending on the specific project and local building codes.

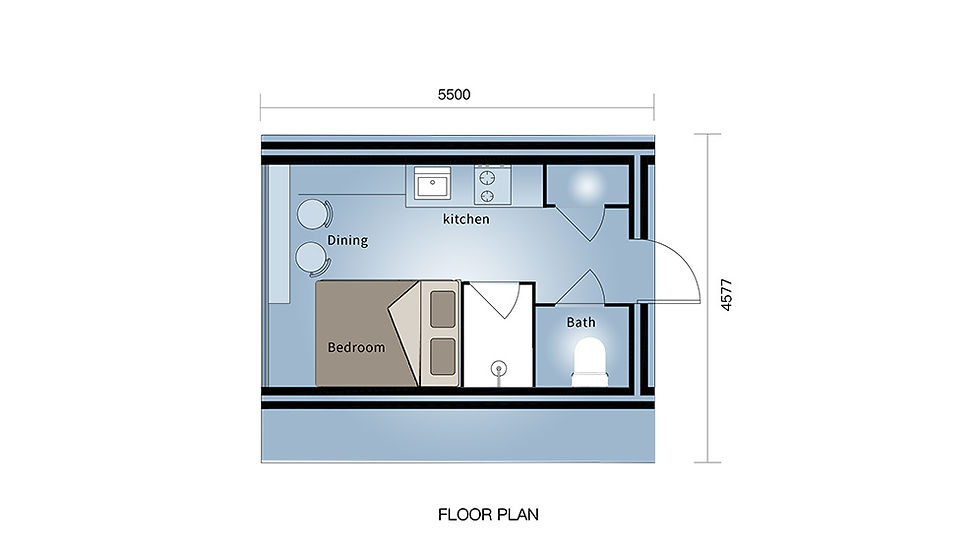

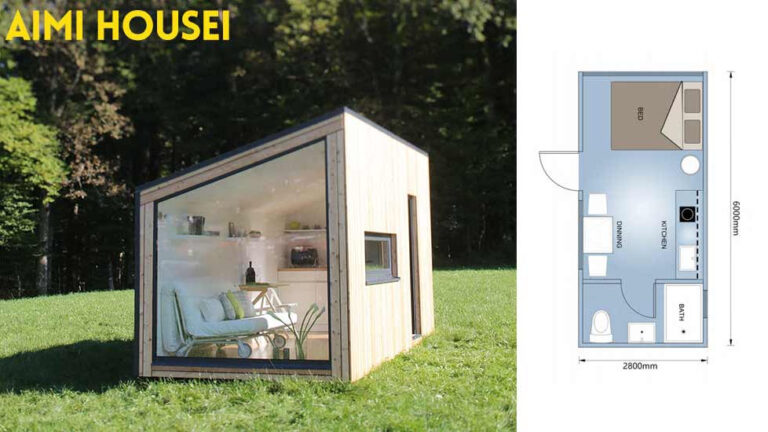

Product parameters

| 01 | Model: | Horn Cabin |

| 02 | Length | 5500mm |

| 03 | Width | 4577mm |

| 04 | Height | 3800mm |

| 05 | Area: | 25.17 ㎡ |

Benefits of Cold-Formed Steel Framing

When it comes to framing materials for prefabricated structures, Cold-formed steel (CFS) stands out as the superior choice for several compelling reasons. CFS is:

- Precision Engineering: CFS is pre-engineered and can be cut to exact lengths, ensuring a perfect fit for your construction needs.

- Dimensional Stability:Unlike materials like wood or concrete, CFS remains dimensionally stable and doesn’t expand or contract with changes in moisture content, guaranteeing long-term structural integrity.

- Lightweight Efficiency: CFS is remarkably lightweight compared to traditional alternatives, making it easier to handle and transport, saving both time and resources.

- Weather-Resistant:CFS exhibits exceptional resilience. It won’t warp, split, crack, or creep when exposed to the elements, ensuring your structures endure the test of time.

- Sustainability:With a 100% recyclable nature, CFS is an eco-conscious choice that contributes to sustainable construction practices and a greener future.

- High Tensile Strength:CFS boasts impressive tensile strength, ensuring the structural reliability and longevity of your projects.

- Fire Safety: Non-combustible in nature, CFS serves as a valuable safeguard against fire accidents, prioritizing safety in your constructions.

Choose the advantages of Cold-formed steel framing for your next project and experience a new level of efficiency, durability, and sustainability in your construction endeavors.

Price

Please reach out to our sales team for pricing details.