The Vienna House is a magnificent double-row villa designed and manufactured by DeepBlue Smarthouse using light steel frame house technology. This stunning home spans an impressive 450 square meters and is located in Ningbo, with a project completion date of October 2020.

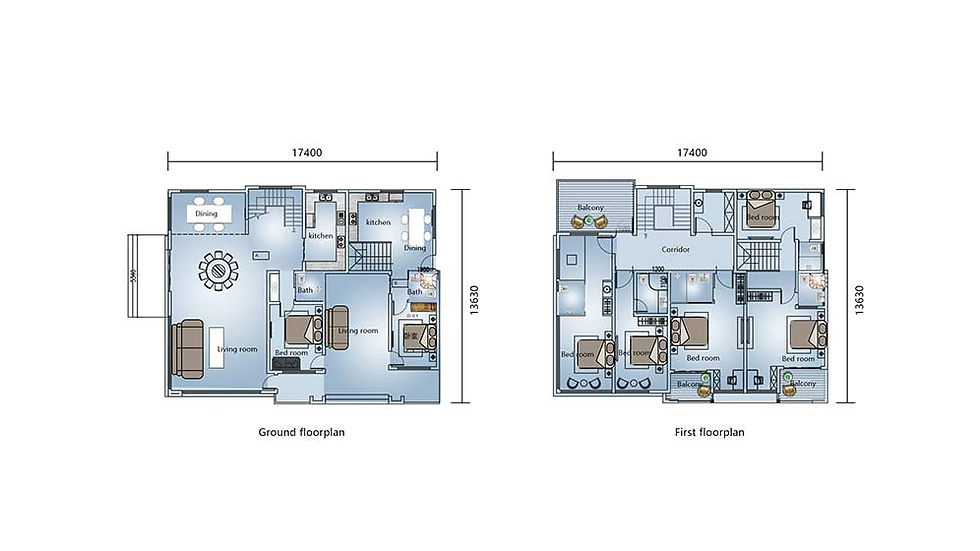

This unique villa is designed to be a duplex, with two adjoining homes that have separate entrances and shared walls. However, to ensure privacy and a sense of individuality for the residents, the designer has positioned the two houses’ front doors in different directions, allowing them to coexist without disturbing each other’s privacy.

The ground floor of the Vienna House has a spacious living room and a modern kitchen, providing ample space for relaxation and entertainment. The first floor is equipped with seven bedrooms and seven bathrooms, providing a comfortable and private space for the residents.

The Vienna House is built with light steel frame house technology, which offers superior durability, flexibility, and energy efficiency. This material is also easy to assemble and disassemble, making it an excellent choice for construction in challenging or remote locations.

Overall, the Vienna House is a prime example of DeepBlue Smarthouse’s commitment to providing high-quality and innovative housing solutions to meet the needs of modern homeowners.

DEEPBLUE SMARTHOUSE has been specializing in the production and manufacture of light steel houses for 14 years, and has rich industry experience and a strong factory. Our team of professional designers and personnel ensures high-quality and efficient construction of each project. Whether you are looking for a compact and efficient home or a spacious and luxurious villa, DEEPBLUE SMARTHOUSE has a solution to meet your needs.

Product parameters

| 01 | Model: | Vienna House |

| 02 | Size: | 17400×13630mm |

| 03 | Ground Floor Area: | 235 ㎡ |

| 04 | First Floor Area: | 215 ㎡ |

| 05 | Total area: | 450 ㎡ |

| 06 | Supplier: | DeepBlue |

| 07 | Project location: | Ningbo |

| 08 | Project date: | 2020/10 |

Benefits of Cold-Formed Steel Framing

When it comes to framing materials for prefabricated structures, Cold-formed steel (CFS) stands out as the superior choice for several compelling reasons. CFS is:

- Precision Engineering: CFS is pre-engineered and can be cut to exact lengths, ensuring a perfect fit for your construction needs.

- Dimensional Stability:Unlike materials like wood or concrete, CFS remains dimensionally stable and doesn’t expand or contract with changes in moisture content, guaranteeing long-term structural integrity.

- Lightweight Efficiency: CFS is remarkably lightweight compared to traditional alternatives, making it easier to handle and transport, saving both time and resources.

- Weather-Resistant:CFS exhibits exceptional resilience. It won’t warp, split, crack, or creep when exposed to the elements, ensuring your structures endure the test of time.

- Sustainability:With a 100% recyclable nature, CFS is an eco-conscious choice that contributes to sustainable construction practices and a greener future.

- High Tensile Strength:CFS boasts impressive tensile strength, ensuring the structural reliability and longevity of your projects.

- Fire Safety: Non-combustible in nature, CFS serves as a valuable safeguard against fire accidents, prioritizing safety in your constructions.

Choose the advantages of Cold-formed steel framing for your next project and experience a new level of efficiency, durability, and sustainability in your construction endeavors.

Price

Please reach out to our sales team for pricing details.