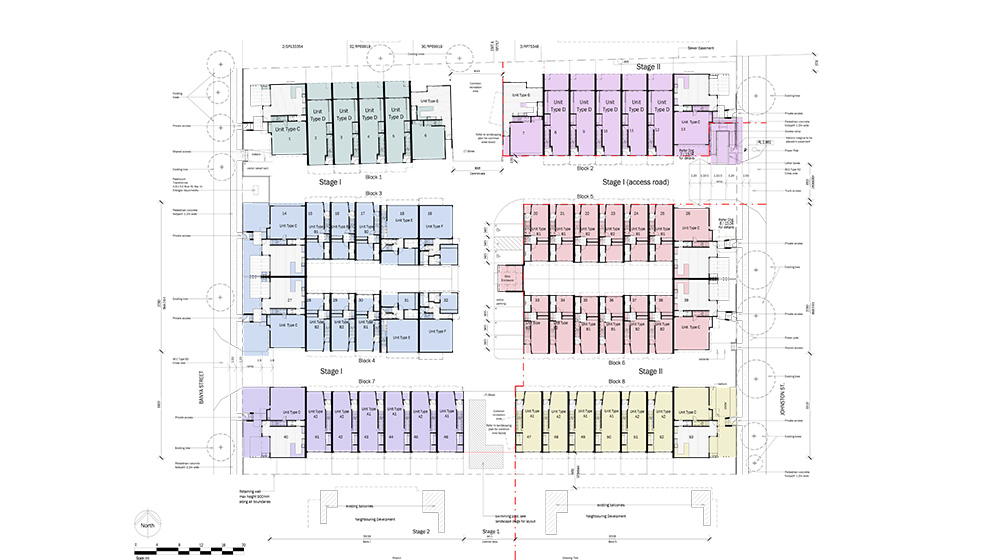

54 sets 3 floors apartments in Brisbane, Australia

The Brisbane project, located in Australia, was designed and manufactured by DeepBlue SmartHouse using light steel frame construction technology. This project includes 54 sets of 3-floor townhouses, covering an area of over 10,000 square meters.

The Brisbane house design offers a spacious living environment, even on a small block of land. With a variety of upstairs floor plans, the home can accommodate various needs, from a luxurious hotel-style master suite to an additional fourth bedroom to allow for family growth.

DeepBlue SmartHouse’s light steel frame construction technology provides a range of benefits, including durability, energy efficiency, and fast construction times. The use of steel framing also allows for greater flexibility in design and layout, which was a key factor in the success of the Brisbane project.

The project was completed in 2018 and has been well-received by residents and visitors alike. The use of light steel frame construction technology has allowed for the creation of a modern and spacious living environment that meets the needs of a growing community.

In conclusion, the Brisbane project is an excellent example of the capabilities of DeepBlue SmartHouse in designing and manufacturing high-quality light steel frame houses. The project’s success has proven the benefits of using this construction technology, including increased durability, energy efficiency, and flexibility in design.

DEEPBLUE SMARTHOUSE has been specializing in the production and manufacture of light steel houses for 14 years, and has rich industry experience and a strong factory. Our team of professional designers and personnel ensures high-quality and efficient construction of each project. Whether you are looking for a compact and efficient home or a spacious and luxurious villa, DEEPBLUE SMARTHOUSE has a solution to meet your needs.

Product parameters

| 01 | Project site: | Brisbane, Australia |

| 02 | Project date: | 2018/10 |

| 03 | Area: | Over 10000sqm |

| 04 | Supplier: | DeepBlue |

| 05 | Project location: | 54 sets 3 floors town house |

Benefits of Cold-Formed Steel Framing

When it comes to framing materials for prefabricated structures, Cold-formed steel (CFS) stands out as the superior choice for several compelling reasons. CFS is:

- Precision Engineering: CFS is pre-engineered and can be cut to exact lengths, ensuring a perfect fit for your construction needs.

- Dimensional Stability:Unlike materials like wood or concrete, CFS remains dimensionally stable and doesn’t expand or contract with changes in moisture content, guaranteeing long-term structural integrity.

- Lightweight Efficiency: CFS is remarkably lightweight compared to traditional alternatives, making it easier to handle and transport, saving both time and resources.

- Weather-Resistant:CFS exhibits exceptional resilience. It won’t warp, split, crack, or creep when exposed to the elements, ensuring your structures endure the test of time.

- Sustainability:With a 100% recyclable nature, CFS is an eco-conscious choice that contributes to sustainable construction practices and a greener future.

- High Tensile Strength:CFS boasts impressive tensile strength, ensuring the structural reliability and longevity of your projects.

- Fire Safety: Non-combustible in nature, CFS serves as a valuable safeguard against fire accidents, prioritizing safety in your constructions.

Choose the advantages of Cold-formed steel framing for your next project and experience a new level of efficiency, durability, and sustainability in your construction endeavors.

Price

Please reach out to our sales team for pricing details.